Texture analysis

We've pulled together some of our favourite texture analysis case studies, application examples, example videos and product introductions.

Discover more about tensile testing, including over 50 documented customer example applications, customer testimonials and more at Mecmesin.com (tensile strength).

Texture analysis test examples and product videos

Case studies and customer examples

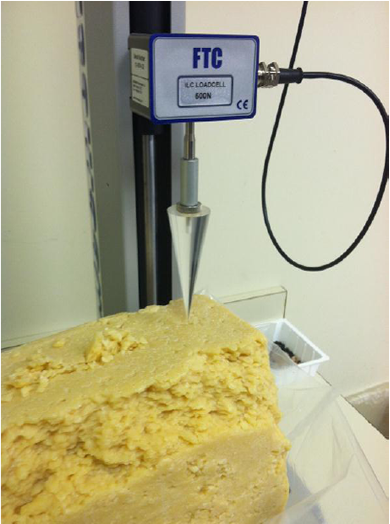

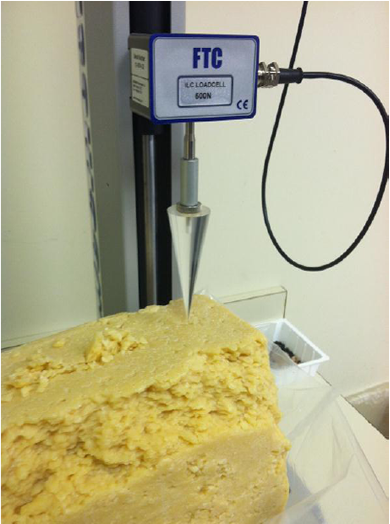

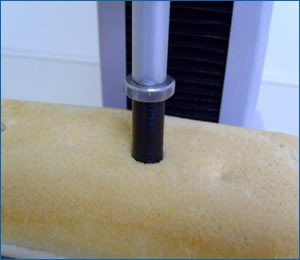

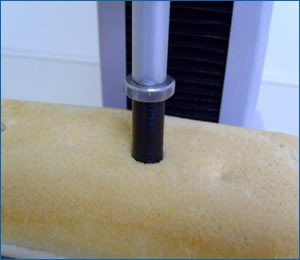

Cheese springiness

Situation

The following case study was performed with the goal of developing a method to measure the springiness of a cheese sample. In its most simple terms, springiness refers to how a product “springs” back after being compressed to a certain distance. This characteristic can also be referred to as elasticity, which is how a product retains its original form after being compressed. In regards to texture, this property is an indication of how the food product will behave during the process of mastication.

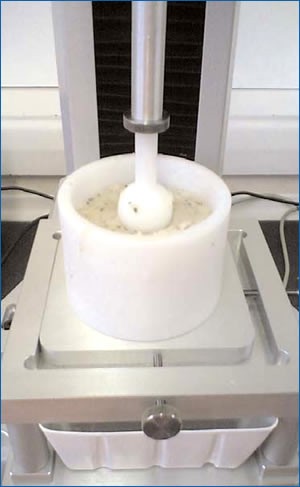

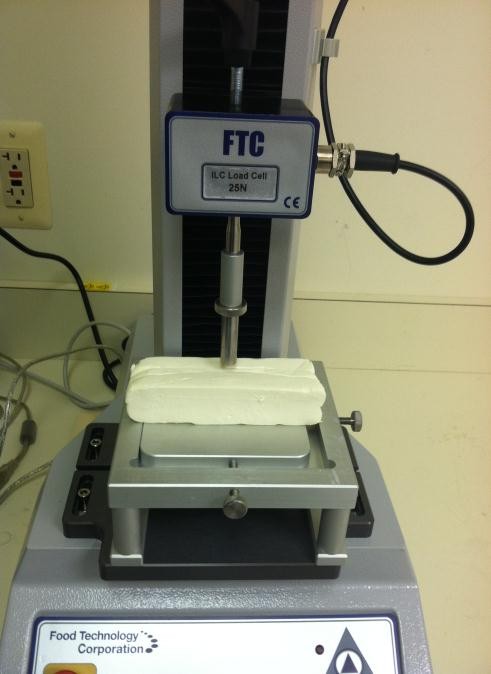

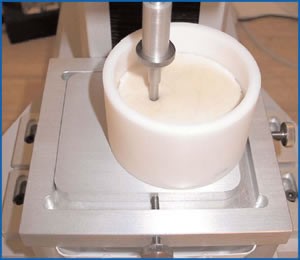

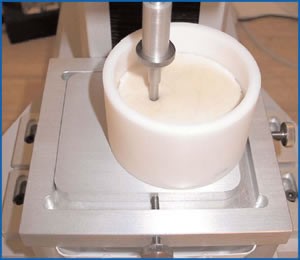

Powder characterization using a cone probe

Application

While texture testing is often used to determine the quality of final products, it can also be used to characterize raw ingredients. Powder is a form that is typical of incoming raw product.

While texture testing is often used to determine the quality of final products, it can also be used to characterize raw ingredients. Powder is a form that is typical of incoming raw product.

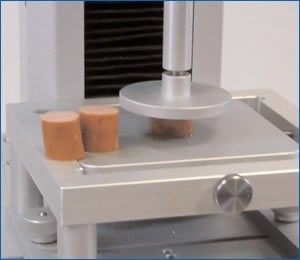

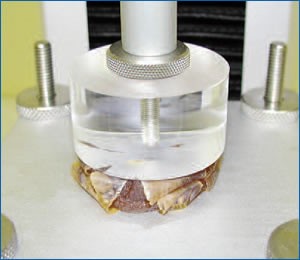

Raw almond cutting force

Application

Several varieties of raw almonds were provided as part of a study to develop a method that would allow the processor to better understand how the products were going to behave in the slicing process.

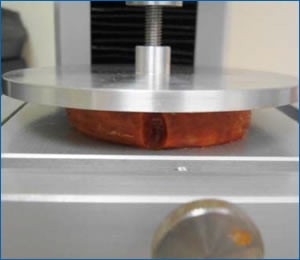

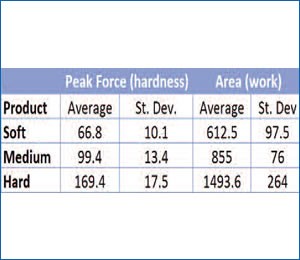

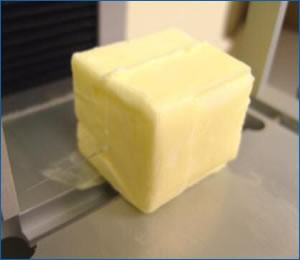

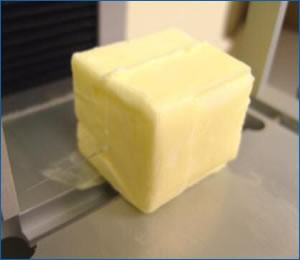

What is ISO 16305 (Butter - Determination of firmness)?

ISO 16035 is a standard that outlines the method for determining the firmess of butter using a texture analyzer. The method involves compressing a sample of butter using a cutting wire probe under controlled conditions and measuring the force required to compress the sample.

The results provide information about the firmness and consistency of the butter, which can be used to assess quality and make decisions about product formulation and processing.

Popcorn crunchiness texture cooking process comparison

Situation

Two hot air samples were prepared in commercially available home-cook popcorn poppers. The two microwaveable samples were heated in a microwave oven for three minutes. All samples were allowed to cool to room temperature before being analyzed. After cooling, 5 g samples were placed in the Kramer CS-1 Standard Shear Compression Cell for testing.

อภิธานศัพท์: คำศัพท์เกี่ยวกับเนื้อสัมผัสอาหาร

คำอธิบายของอาหารเครื่องสำอางและพื้นผิวผลิตภัณฑ์ยามาจากปัจจัยการรับสัมผัสจากการสัมผัสทางกายภาพรวมถึงการสัมผัสด้วยนิ้วและปาก

ต่อไปนี้เป็นรายการคำศัพท์ที่ครอบคลุมทุกด้านของการวัดพื้นผิวอาหารและผลิตภัณฑ์ที่มีการตัดสินทางประสาทสัมผัสที่คล้ายกันเช่นเครื่องสำอางและยา

Glossary: Terminology of food texture

The description of food, cosmetics and pharmaceutical product texture is derived from sensory inputs from physical contact, including finger-feel and mouth-feel.

The following is a list of terms covering all aspects of food texture measurement and similar sensory-judged products, such as cosmetics and pharmaceuticals.

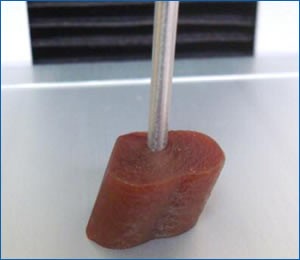

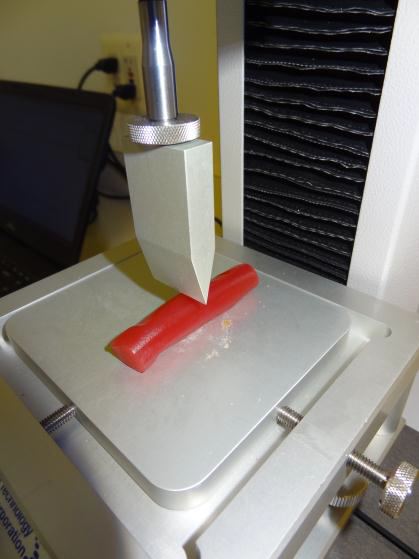

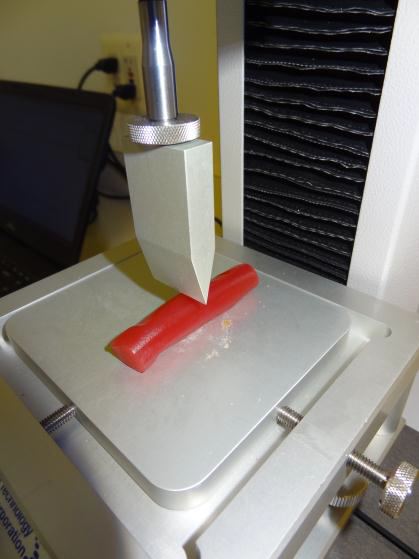

Lipstick shear force resistance

Requirement

Lipstick holds the top spot in the hierarchy of makeup with its ability to completely transform appearance without the help of any other beauty product. One investigation by a beauty magazine concluded that the average consumer applies up to nine pounds of lipstick in their lifetime, so it’s no wonder that so much attention is focused on getting this little tube of oil / wax / colouring agent to perform consistently every time. The result not only needs to look good, with lasting results, but mustn’t bend, crack, crumble or break when applied.

ความต้านทานแรงเฉือนของลิปสติก

ความต้องการ

ลิปสติกถือเป็นจุดสูงสุดในลำดับชั้นของการแต่งหน้าที่มีความสามารถในการแปลงโฉมอย่างสมบูรณ์โดยไม่ต้องใช้ผลิตภัณฑ์เสริมความงามอื่น การตรวจสอบโดยนิตยสารด้านความงามสรุปว่าผู้บริโภคทั่วไปใช้ลิปสติกมากถึง 9 ปอนด์ในช่วงชีวิตของพวกเขาดังนั้นจึงไม่น่าแปลกใจเลยที่ความสนใจจำนวนมากมุ่งเน้นไปที่การรับตัวแทนน้ำมัน / ขี้ผึ้ง / สีหลอดเล็ก ๆ นี้ ผลลัพธ์ที่ได้ไม่เพียง แต่ต้องดูดีมีผลลัพธ์ที่ยั่งยืน แต่ต้องไม่งอแตกร่วนหรือแตกเมื่อใช้

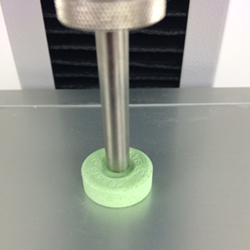

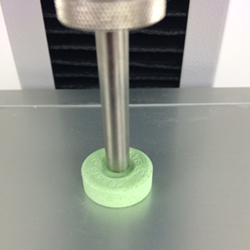

Granule hardness test

Requirement

Ecosyl Products Limited is one of the world's leading companies involved in the sales and marketing of forage additives for the agricultural industry. Ecosyl uses its own patented production technology to produce a range of silage additives.

Ecosyl scientists wanted to be able to assess the potassium sorbate they receive from suppliers, in order to increase the shelf life of products and ensure their physical integrity throughout the production process. This required a hardness test to be performed on multiple granule particulates.

The Mecmesin test system allows us to assess the ability of our potassium sorbate suppliers to provide a grade that will not physically deteriorate through blending and storage, yet will enable us to extend the shelf life of our products, whilst enjoying the savings from reduced manufacturing costs. Mecmesin were exceedingly helpful at first contact and were very knowledgeable and professional throughout the process of test development. The company made great effort to ensure we achieved a working, reliable, repeatable and reproducible system that met all our requirements at a sensible price.

Gordon Marley, Senior Scientist - R&D

Ecosyl

การทดสอบความแข็งแกรนูล

ความต้องการ

Ecosyl Products Limited เป็นหนึ่งใน บริษัท ชั้นนำของโลกที่มีส่วนร่วมในการขายและการตลาดของสารเติมแต่งอาหารสัตว์สำหรับอุตสาหกรรมการเกษตร Ecosyl ใช้เทคโนโลยีการผลิตที่จดสิทธิบัตรของตัวเองเพื่อผลิตสารเติมแต่งหมักหลากหลายชนิด

นักวิทยาศาสตร์ Ecosyl ต้องการประเมินโพแทสเซียมซอร์เบตที่ได้รับจากซัพพลายเออร์เพื่อเพิ่มอายุการเก็บรักษาของผลิตภัณฑ์และให้ความสมบูรณ์ทางกายภาพตลอดกระบวนการผลิต สิ่งนี้จำเป็นต้องมีการทดสอบความแข็งที่จะดำเนินการกับอนุภาคหลายเม็ด

ระบบทดสอบของเมกมีซินช่วยให้เราประเมินความสามารถของซัพพลายเออร์โพแทสเซียมซอร์เบตในการให้เกรดที่จะไม่เสื่อมสภาพทางร่างกายผ่านการผสมและการเก็บรักษา แต่จะช่วยยืดอายุการเก็บรักษาผลิตภัณฑ์ของเรา . เมกมีซินมีประโยชน์อย่างมากในการติดต่อครั้งแรกและมีความรู้และเป็นมืออาชีพตลอดกระบวนการพัฒนาแบบทดสอบ บริษัท ได้ใช้ความพยายามอย่างยิ่งใหญ่เพื่อให้แน่ใจว่าเราได้รับระบบการทำงานที่เชื่อถือได้ทำซ้ำและทำซ้ำได้ซึ่งตรงตามข้อกำหนดทั้งหมดของเราในราคาที่สมเหตุสมผล

Gordon Marley นักวิทยาศาสตร์อาวุโส - R&D

Ecosyl

ประโยชน์ของการวิเคราะห์เนื้อสัมผัสในการผลิตอาหาร

พื้นผิวและความรู้สึกของอาหารที่เกี่ยวข้องมีบทบาทสำคัญในการประเมินผลิตภัณฑ์ของผู้บริโภค ในบางกรณีลักษณะเหล่านี้สำคัญกว่ารสชาติลักษณะหรือกลิ่น พื้นผิวหมายถึงลักษณะทางกายภาพของอาหารที่ถูกประมวลผลโดยสมองในระหว่างการบด Mouthfeel มีความสัมพันธ์กับเนื้อสัมผัสซึ่งหมายถึงปฏิสัมพันธ์ระหว่างพื้นผิวในปากและอาหาร ในรูปแบบที่ง่ายที่สุด mouthfeel เป็นแบบนั้น: รู้สึกอย่างไรในปาก ผู้บริโภคมักใช้คำศัพท์ที่แข็งนุ่มกรอบหรือกรุบกรอบในการอธิบายเนื้อสัมผัสของอาหารซึ่งบางส่วนนำไปสู่การติดฉลากเพิ่มเติมเช่นสุกสดหรือเหม็นอับ

ถ้าเนื้อไม่รู้สึกขวาให้กับผู้บริโภคสินค้าจะไม่ได้รับโอกาสที่จะได้ลิ้มรส บริษัท สามารถ ตอบสนองความคาดหวังของผู้บริโภคได้ ดีที่สุด ผ่านการวัด (การทดสอบทางประสาทสัมผัสและการวิเคราะห์พื้นผิว) และการควบคุม (พารามิเตอร์สูตรและการประมวลผล)

Drew Lambert

ผู้จัดการฝ่ายเทคนิค

The benefits of texture analysis in food production

Texture, and the related mouthfeel of food, plays an essential role in how consumers evaluate the product. In some cases, these characteristics are even more important than those of taste, appearance, or smell. Texture refers to how the physical attributes of the food are processed by the brain during mastication. Mouthfeel is related to texture in that it refers to the interactions between the surfaces in the mouth and the food. In its most simple form, mouthfeel is exactly that: how it feels in the mouth.

If the texture doesn't feel right to the consumer, the product won't even get the chance to be tasted. Companies can best meet consumer expectations through measurement (sensory testing and texture analysis) and control (formulation and processing parameters).

Drew Lambert

Technical Services Manager

พื้นผิวในการผลิตอาหาร

พื้นผิวและความรู้สึกที่เกี่ยวข้องของผลิตภัณฑ์มีบทบาทสำคัญในการประเมินผู้บริโภคของผลิตภัณฑ์ ในบางกรณีลักษณะเหล่านี้สำคัญกว่ารสชาติลักษณะหรือกลิ่น

พื้นผิวหมายถึงลักษณะทางกายภาพของพื้นผิวอาหารที่ถูกประมวลผลโดยสมองในระหว่างการบด ผู้บริโภคใช้ลักษณะที่แข็งนุ่มกรอบกรุบกรอบเพื่ออธิบายเนื้อสัมผัสของอาหาร

Mouthfeel มีความสัมพันธ์กับเนื้อสัมผัสซึ่งหมายถึงปฏิสัมพันธ์ระหว่างพื้นผิวในปากและอาหาร ในรูปแบบที่ง่ายที่สุด mouthfeel เป็นแบบนั้น: รู้สึกอย่างไรในปาก

ในฐานะผู้บริโภคเรามีเนื้อและปากที่ต้องการฝังอยู่ในสมองของเราสำหรับการบริโภคแต่ละครั้งที่เรากิน

มีเพียงไม่กี่คนที่เข้าใจถึงความยาวพิเศษที่ผู้ผลิตอาหารดำเนินการเพื่อให้แน่ใจว่าเราได้รับสิ่งที่เราคาดหวังทุกครั้ง

Drew Lambert

ผู้จัดการฝ่ายเทคนิค

Texture in food production

Texture, and the related mouthfeel of a product, plays an essential role in how consumers evaluate a product. In some cases, these characteristics are even more important than those of taste, appearance, or smell.

Texture refers to how the physical attributes of a food texture are processed by the brain during mastication. Characteristics like hard, soft, crispy, crunchy, are used by consumers to describe food texture.

As consumers, we have a desired texture and mouthfeel ingrained in our brain for each consumable that we eat.

Few of us understand the extraordinary lengths to which food manufacturers go to ensure that we get exactly what we expect every time.

Drew Lambert

Technical Services Manager

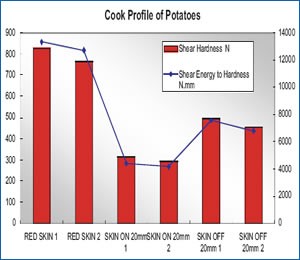

Potato softness grading for salad

Application

Measuring texture of diced potatoes used in potato salads.

Problem

A processor of diced potatoes was relying on inconsistent, subjective sensory results to measure the texture of their product. Therefore, they needed a quantifiable, consistent and repeatable way to measure their product and implement a standardized range of 'ideal' product.

Solution

การคัดเกรดมันฝรั่งสำหรับสลัด

ใบสมัคร

การวัดพื้นผิวของมันฝรั่งหั่นสี่เหลี่ยมลูกเต๋าที่ใช้ในสลัดมันฝรั่ง

ปัญหา

หน่วยประมวลผลของมันฝรั่งหั่นสี่เหลี่ยมลูกเต๋านั้นขึ้นอยู่กับผลลัพธ์ทางประสาทสัมผัสที่ไม่สอดคล้องกันและอัตนัยในการวัดพื้นผิวของผลิตภัณฑ์ของพวกเขา ดังนั้นพวกเขาจึงต้องการวิธีการวัดปริมาณที่สม่ำเสมอและทำซ้ำได้ในการวัดผลิตภัณฑ์ของพวกเขาและใช้ผลิตภัณฑ์ 'อุดมคติ' ที่เป็นมาตรฐาน

สารละลาย

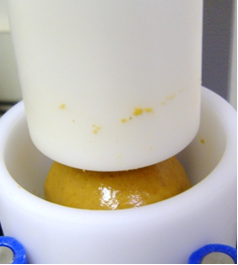

Gel Capsule Rupture Strength

Requirement

A pharmaceutical company needed a way to measure the force required to rupture gel capsules. The force is an indication of the thickness of the shell of the gel caps. A wall that is too thin will not hold its shape, while one that is too thick will not dissolve properly. These caps are used in healthcare, nutrition and pharmaceutical delivery.

A pharmaceutical company needed a way to measure the force required to rupture gel capsules. The force is an indication of the thickness of the shell of the gel caps. A wall that is too thin will not hold its shape, while one that is too thick will not dissolve properly. These caps are used in healthcare, nutrition and pharmaceutical delivery.

เจลแคปซูลแตกแข็งแรง

ความต้องการ

บริษัท ยาต้องการวิธีการวัดแรงที่ต้องใช้ในการแตกแคปซูลเจล แรงเป็นตัวบ่งชี้ความหนาของเปลือกของฝาเจล ผนังที่บางเกินไปจะไม่สามารถยึดรูปร่างได้ในขณะที่ผนังที่หนาเกินไปจะไม่ละลายอย่างเหมาะสม หมวกเหล่านี้ใช้ในการดูแลสุขภาพโภชนาการและการส่งมอบยา

บริษัท ยาต้องการวิธีการวัดแรงที่ต้องใช้ในการแตกแคปซูลเจล แรงเป็นตัวบ่งชี้ความหนาของเปลือกของฝาเจล ผนังที่บางเกินไปจะไม่สามารถยึดรูปร่างได้ในขณะที่ผนังที่หนาเกินไปจะไม่ละลายอย่างเหมาะสม หมวกเหล่านี้ใช้ในการดูแลสุขภาพโภชนาการและการส่งมอบยา

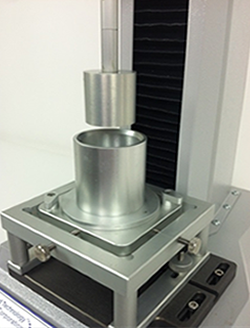

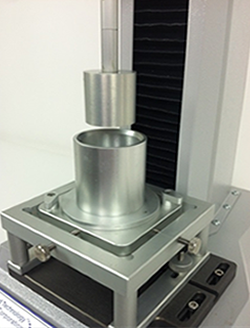

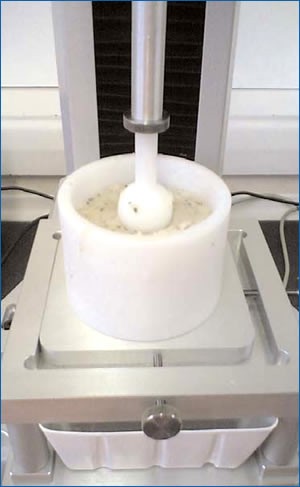

Gelatin Bloom Strength Testing

Samples of commercial gelatin (gelatine) were prepared and evaluated following recommendations from the Gelatine Manufacturers of Europe (GME) Monograph 2004 and ISO 9665.

การทดสอบความแข็งแรงของเจลาตินบลูม

ตัวอย่างของเจลาตินเชิงพาณิชย์ได้จัดทำและประเมินตามคำแนะนำจากผู้ผลิตเจลาตินแห่งยุโรป (GME) Monograph 2004 และ ISO 9665

ตัวอย่างของเจลาตินเชิงพาณิชย์ได้จัดทำและประเมินตามคำแนะนำจากผู้ผลิตเจลาตินแห่งยุโรป (GME) Monograph 2004 และ ISO 9665

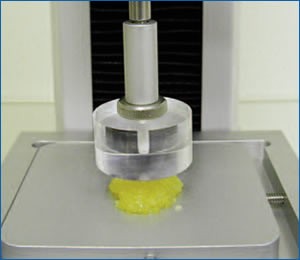

Mayonnaise Consistency Regular and Low Fat

Introduction

The following data was gathered for a manufacturer of mayonnaise in an effort to develop a repeatable method for comparing their regular and low fat products. Currently, the product is evaluated using rudimentary sensory methods. While sensory is very important, it is subjective and varies from person to person.

The following data was gathered for a manufacturer of mayonnaise in an effort to develop a repeatable method for comparing their regular and low fat products. Currently, the product is evaluated using rudimentary sensory methods. While sensory is very important, it is subjective and varies from person to person.

มายองเนสที่สอดคล้องสม่ำเสมอและไขมันต่ำ

บทนำ

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับผู้ผลิตมายองเนสในความพยายามที่จะพัฒนาวิธีการทำซ้ำเพื่อเปรียบเทียบผลิตภัณฑ์ปกติและไขมันต่ำของพวกเขา ปัจจุบันผลิตภัณฑ์ได้รับการประเมินโดยใช้วิธีการทางประสาทสัมผัสเบื้องต้น ในขณะที่ประสาทสัมผัสเป็นสิ่งสำคัญมากมันเป็นเรื่องส่วนตัวและแตกต่างจากคนสู่คน

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับผู้ผลิตมายองเนสในความพยายามที่จะพัฒนาวิธีการทำซ้ำเพื่อเปรียบเทียบผลิตภัณฑ์ปกติและไขมันต่ำของพวกเขา ปัจจุบันผลิตภัณฑ์ได้รับการประเมินโดยใช้วิธีการทางประสาทสัมผัสเบื้องต้น ในขณะที่ประสาทสัมผัสเป็นสิ่งสำคัญมากมันเป็นเรื่องส่วนตัวและแตกต่างจากคนสู่คน

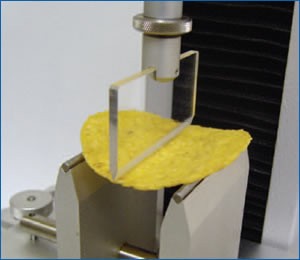

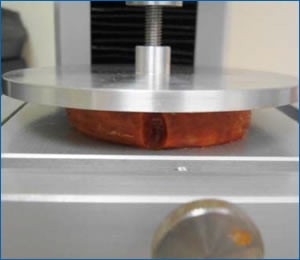

Pork pie crust firmness

Situation

Vale of Mowbray has been baking pork pies since 1928. Having traditionally relied on sensory perception, where results are qualitative and could be biased, the company now needed an objective way of measuring the quality and consistency of their cooked and uncooked produce. Pastry crust texture should have the right combination of firmness, crispness and ease of penetration to ensure quality in cutting, biting and mouthfeel.

แป้งพายหมูแน่น

สถานการณ์

Vale of Mowbray ทำขนมพายหมูมาตั้งแต่ปี 2471 โดยอาศัยการรับรู้ทางประสาทสัมผัสซึ่งผลลัพธ์นั้นมีคุณภาพและสามารถลำเอียงปัจจุบัน บริษัท ต้องการวิธีการวัดคุณภาพและความสม่ำเสมอของผลิตภัณฑ์ที่ปรุงสุกและไม่สุก พื้นผิวของขนมอบควรมีการผสมผสานที่ลงตัวของความแน่นความกรอบและความง่ายในการเจาะเพื่อให้ได้คุณภาพในการตัดกัดและปาก

Pumpkin (processed) filling firmness and consistency

Situation

Processed pumpkin filling is typically sold as a processed, canned product. For this particular method, the processor was interested in having more complete understanding as to how certain variables in the formulation can affect the final product.

Processed pumpkin filling is typically sold as a processed, canned product. For this particular method, the processor was interested in having more complete understanding as to how certain variables in the formulation can affect the final product.

ฟักทอง (ผ่านการแปรรูป) เติมความแน่นและความมั่นคง

สถานการณ์

โดยทั่วไปแล้วไส้ฟักทองที่ผ่านการแปรรูปแล้วจะถูกจำหน่ายเป็นผลิตภัณฑ์แปรรูป สำหรับวิธีการเฉพาะนี้ผู้ประมวลผลสนใจที่จะมีความเข้าใจที่สมบูรณ์มากขึ้นว่าตัวแปรบางอย่างในการกำหนดสามารถส่งผลกระทบต่อผลิตภัณฑ์ขั้นสุดท้ายได้อย่างไร รูปแบบเหล่านี้อาจรวมถึงความแตกต่างหลากหลายในการจัดหาวัตถุดิบที่เข้ามาการเปลี่ยนแปลงส่วนผสมเงื่อนไขการจัดเก็บและพารามิเตอร์การปรุง สำหรับกรณีศ

โดยทั่วไปแล้วไส้ฟักทองที่ผ่านการแปรรูปแล้วจะถูกจำหน่ายเป็นผลิตภัณฑ์แปรรูป สำหรับวิธีการเฉพาะนี้ผู้ประมวลผลสนใจที่จะมีความเข้าใจที่สมบูรณ์มากขึ้นว่าตัวแปรบางอย่างในการกำหนดสามารถส่งผลกระทบต่อผลิตภัณฑ์ขั้นสุดท้ายได้อย่างไร รูปแบบเหล่านี้อาจรวมถึงความแตกต่างหลากหลายในการจัดหาวัตถุดิบที่เข้ามาการเปลี่ยนแปลงส่วนผสมเงื่อนไขการจัดเก็บและพารามิเตอร์การปรุง สำหรับกรณีศ

Candy Cane Snap Testing

Situation

One of the qualities of a good candy cane is its brittleness: not being bendy, tough and chewy. You can tell a good candy cane apart, by breaking it in your hands. But how brittle is how good, and where and how does it break? When is a candy cane past its best? Or will it break during packaging and transport—and can you manufacture a better product to a more consistent formula?

One of the qualities of a good candy cane is its brittleness: not being bendy, tough and chewy. You can tell a good candy cane apart, by breaking it in your hands. But how brittle is how good, and where and how does it break? When is a candy cane past its best? Or will it break during packaging and transport—and can you manufacture a better product to a more consistent formula?

การทดสอบ Snap Candy Cane

สถานการณ์

หนึ่งในคุณสมบัติของอ้อยขนมที่ดีคือความเปราะบางของมัน: ไม่บิดงอ, เหนียวและเหนียว คุณสามารถแยกแยะอ้อยขนมดี ๆ โดยแยกมันไว้ในมือของคุณ แต่เปราะเป็นอย่างไรดีอย่างไรและมันแตกที่ไหนและอย่างไร เมื่ออ้อยขนมผ่านมาดีที่สุดเมื่อใด หรือมันจะแตกระหว่างการบรรจุหีบห่อและการขนส่งและคุณสามารถผลิตผลิตภัณฑ์ที่ดีกว่าให้เป็นสูตรที่สอดคล้องกันมากขึ้นได้หรือไม่?

หนึ่งในคุณสมบัติของอ้อยขนมที่ดีคือความเปราะบางของมัน: ไม่บิดงอ, เหนียวและเหนียว คุณสามารถแยกแยะอ้อยขนมดี ๆ โดยแยกมันไว้ในมือของคุณ แต่เปราะเป็นอย่างไรดีอย่างไรและมันแตกที่ไหนและอย่างไร เมื่ออ้อยขนมผ่านมาดีที่สุดเมื่อใด หรือมันจะแตกระหว่างการบรรจุหีบห่อและการขนส่งและคุณสามารถผลิตผลิตภัณฑ์ที่ดีกว่าให้เป็นสูตรที่สอดคล้องกันมากขึ้นได้หรือไม่?

Corn Chip Snack Crispness

The Application

A large manufacturer of snack food items was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

A large manufacturer of snack food items was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

Problem

ข้าวโพดกรอบสแน็คกรอบ

แอพพลิเคชั่น

ผู้ผลิตขนมขบเคี้ยวรายใหญ่รายหนึ่งกำลังมองหาวิธีการวัดเชิงปริมาณและสม่ำเสมอในที่สุดและควบคุมพื้นผิวของผลิตภัณฑ์ได้ดีที่สุด วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

ผู้ผลิตขนมขบเคี้ยวรายใหญ่รายหนึ่งกำลังมองหาวิธีการวัดเชิงปริมาณและสม่ำเสมอในที่สุดและควบคุมพื้นผิวของผลิตภัณฑ์ได้ดีที่สุด วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

ปัญหา

Canned Tuna Firmness

Situation

Is this can of tuna of the right texture? Which part of it? Testing for firmness has frequently meant expert but subjective judgment. How can these assessments be correlated with objective measurements for reliable and repeatable testing?

Is this can of tuna of the right texture? Which part of it? Testing for firmness has frequently meant expert but subjective judgment. How can these assessments be correlated with objective measurements for reliable and repeatable testing?

ปลาทูน่าบรรจุกระป๋อง

สถานการณ์

นี่เป็นปลาทูน่าที่มีเนื้อสัมผัสที่ถูกต้องหรือไม่? ส่วนไหนของมัน? การทดสอบความแน่วแน่มีความหมายผู้เชี่ยวชาญบ่อยครั้ง แต่เป็นการตัดสินใจเชิงอัตวิสัย การประเมินเหล่านี้จะมีความสัมพันธ์กับการวัดที่เป็นกลางสำหรับการทดสอบที่เชื่อถือได้และทำซ้ำได้อย่างไร?

นี่เป็นปลาทูน่าที่มีเนื้อสัมผัสที่ถูกต้องหรือไม่? ส่วนไหนของมัน? การทดสอบความแน่วแน่มีความหมายผู้เชี่ยวชาญบ่อยครั้ง แต่เป็นการตัดสินใจเชิงอัตวิสัย การประเมินเหล่านี้จะมีความสัมพันธ์กับการวัดที่เป็นกลางสำหรับการทดสอบที่เชื่อถือได้และทำซ้ำได้อย่างไร?

Salami Skin Peel Force

Situation

A Dutch salami producer required a method to reproducibly quantify the peel profile of artificial sausage casings. The method had to take into account:

A Dutch salami producer required a method to reproducibly quantify the peel profile of artificial sausage casings. The method had to take into account:

• maturation and storage conditions

• pre-test handling

• sample preparation and fixing

กองทัพลอกผิวซาลามี่

สถานการณ์

ผู้ผลิตซาลามี่ชาวดัตช์ต้องการวิธีการในการทำซ้ำปริมาณการลอกของปลอกไส้กรอกเทียม วิธีการที่ต้องคำนึงถึง:

ผู้ผลิตซาลามี่ชาวดัตช์ต้องการวิธีการในการทำซ้ำปริมาณการลอกของปลอกไส้กรอกเทียม วิธีการที่ต้องคำนึงถึง:

•สภาพการเจริญเติบโตและการเก็บรักษา

•การจัดการก่อนการทดสอบ

•การเตรียมตัวอย่างและการแก้ไข

ความแน่นของข้าวและคุณลักษณะเฉพาะของข้าวหุง

การทดสอบ

เนื้อสัมผัสของข้าวมีความสำคัญมากที่ทำให้ผู้บริโภครับรู้ได้ถึงคุณภาพของผลิตภัณฑ์ น่าเสียดายที่เนื้อสัมผัสได้รับผลกระทบจากหลายปัจจัยในระหว่างกระบวนการผลิต สิ่งแรกที่ผู้ผลิตต้องกำหนด คือ คุณภาพของผลิตภัณฑ์ที่รับเข้ามาตั้งแต่ จุดเริ่มต้น การปรับเปลี่ยนในระหว่างกระบวนการผลิตสามารถทำได้เพื่อให้ได้ผลิตภัณฑ์สุดท้ายมีความคงที่ในด้านคุณภาพ

เนื้อสัมผัสของข้าวมีความสำคัญมากที่ทำให้ผู้บริโภครับรู้ได้ถึงคุณภาพของผลิตภัณฑ์ น่าเสียดายที่เนื้อสัมผัสได้รับผลกระทบจากหลายปัจจัยในระหว่างกระบวนการผลิต สิ่งแรกที่ผู้ผลิตต้องกำหนด คือ คุณภาพของผลิตภัณฑ์ที่รับเข้ามาตั้งแต่ จุดเริ่มต้น การปรับเปลี่ยนในระหว่างกระบวนการผลิตสามารถทำได้เพื่อให้ได้ผลิตภัณฑ์สุดท้ายมีความคงที่ในด้านคุณภาพ

Rice Firmness and Cook Profile

Application

The texture of rice is very important to how the consumer perceives the quality of the product. Unfortunately, the texture is affected by several different factors during the processing. The first thing that the producer has to determine is the quality of the incoming product. From this “starting point” adjustments in the processing can be made to produce a consistent end product.

The texture of rice is very important to how the consumer perceives the quality of the product. Unfortunately, the texture is affected by several different factors during the processing. The first thing that the producer has to determine is the quality of the incoming product. From this “starting point” adjustments in the processing can be made to produce a consistent end product.

การทดสอบความผิดปกติของมันฝรั่งทอด

การประเมินลักษณะความกรอบของมันฝรั่งทอดที่ต้มในกาต้มน้ำได้รับการประเมินโดยใช้ชุดประกอบแบบโค้งสามจุดเป็นตัวบ่งชี้การทอด

ความต้องการ

โปรเซสเซอร์มันฝรั่งทอดต้องการให้มีการวัดอย่างมีวัตถุประสงค์เพื่อเสริมและยืนยันข้อมูลอัตนัยที่ได้จากการทดสอบทางประสาทสัมผัส ประเมินตัวอย่างที่แตกต่างกันเก้าตัวอย่าง

ตัวอย่างที่เป็นตัวแทน:

•กรอบเกินไป

• ในอุดมคติ

•ไม่คมชัดพอ

Granola Bar Bite Force Evaluation

The Application

A processor of nutritional and granola bars looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

A processor of nutritional and granola bars looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

Granola Bar Bite Force การประเมินผล

แอพพลิเคชั่น

โปรเซสเซอร์ของบาร์โภชนาการและกราโนล่ากำลังมองหาวิธีการวัดเชิงปริมาณที่สอดคล้องกันและในที่สุดก็สามารถควบคุมพื้นผิวของผลิตภัณฑ์ได้ดีที่สุด วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

โปรเซสเซอร์ของบาร์โภชนาการและกราโนล่ากำลังมองหาวิธีการวัดเชิงปริมาณที่สอดคล้องกันและในที่สุดก็สามารถควบคุมพื้นผิวของผลิตภัณฑ์ได้ดีที่สุด วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

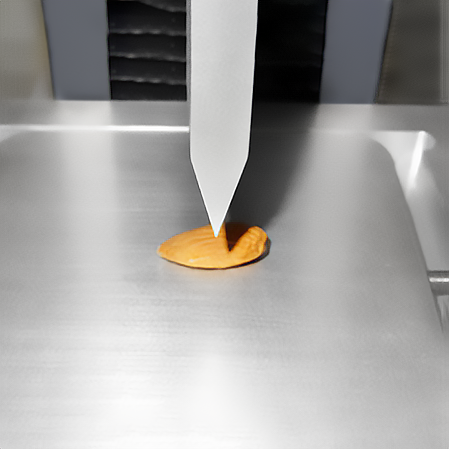

Peanut Butter Flow

The Application

Three samples of a peanut-butter-based product were submitted to determine how to measure their flow characteristics. The product samples were marked good, dry, and wet.

Three samples of a peanut-butter-based product were submitted to determine how to measure their flow characteristics. The product samples were marked good, dry, and wet.

ไหลเนยถั่วลิสง

แอพพลิเคชั่น

มีการส่งตัวอย่างผลิตภัณฑ์เนยถั่วสามตัวอย่างเพื่อกำหนดวิธีการวัดลักษณะการไหล ตัวอย่างผลิตภัณฑ์ถูกระบุว่าดีแห้งและเปียก

มีการส่งตัวอย่างผลิตภัณฑ์เนยถั่วสามตัวอย่างเพื่อกำหนดวิธีการวัดลักษณะการไหล ตัวอย่างผลิตภัณฑ์ถูกระบุว่าดีแห้งและเปียก

ปัญหา

ลูกค้าต้องการวิธีในการพิจารณาว่าเนยถั่วจะทำปฏิกิริยาอย่างไรในระหว่างการประมวลผลก่อนที่จะสร้างผลิตภัณฑ์จริง ปัญหาคือผลิตภัณฑ์ที่เปียกเกินไป (อ่อน) จะไม่คงรูปและผลิตภัณฑ์ที่แห้งเกินไปจะแตก พื้นผิวของผลิตภัณฑ์จะต้องอยู่ในช่วงที่กำหนดเพื่อลดการสร้างผลิตภัณฑ์ที่ใช้ไม่ได้และความล่าช้าในการผลิต

Pasta Firmness and Cook Profile

Situation

A processor of several different kinds of pasta was looking for a more consistent and less time consuming way to control its outgoing product. Current methods involve extensive sensory testing with trained panels. This is very subjective and often tedious to set up.

A processor of several different kinds of pasta was looking for a more consistent and less time consuming way to control its outgoing product. Current methods involve extensive sensory testing with trained panels. This is very subjective and often tedious to set up.

ความแน่นของพาสต้าและ Cook Profile

สถานการณ์

ตัวประมวลผลของพาสต้าชนิดต่าง ๆ กำลังมองหาวิธีที่สอดคล้องกันมากขึ้นและใช้เวลาน้อยลงในการควบคุมผลิตภัณฑ์ที่ส่งออก วิธีการในปัจจุบันเกี่ยวข้องกับการทดสอบทางประสาทสัมผัสอย่างกว้างขวางด้วยแผงฝึก นี่เป็นเรื่องส่วนตัวและมักจะน่าเบื่อในการตั้งค่า

ตัวประมวลผลของพาสต้าชนิดต่าง ๆ กำลังมองหาวิธีที่สอดคล้องกันมากขึ้นและใช้เวลาน้อยลงในการควบคุมผลิตภัณฑ์ที่ส่งออก วิธีการในปัจจุบันเกี่ยวข้องกับการทดสอบทางประสาทสัมผัสอย่างกว้างขวางด้วยแผงฝึก นี่เป็นเรื่องส่วนตัวและมักจะน่าเบื่อในการตั้งค่า

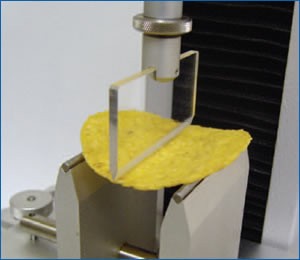

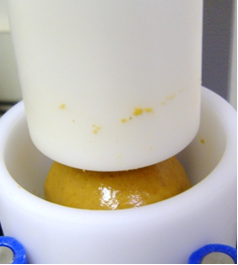

Potato Chip Crispness Test

The crispness characteristics of kettle cooked potato chips were evaluated using a three-point bend assembly as an indicator of frying profile.

Requirement

A potato chip processor wanted to have an objective measurement to supplement and confirm the subjective data they have from sensory testing. Nine different samples were evaluated.

ความแน่นของหอย

สถานการณ์

ตัวอย่างของการสับแปรรูปและหอยทะเลกระป๋องสองตัวอย่างถูกส่งไปประเมินเนื้อสัมผัส

ตัวอย่างของการสับแปรรูปและหอยทะเลกระป๋องสองตัวอย่างถูกส่งไปประเมินเนื้อสัมผัส

Clam Firmness

Situation

Two samples of chopped, processed, and canned sea clams were submitted for texture evaluation.

Two samples of chopped, processed, and canned sea clams were submitted for texture evaluation.

ความแน่นเนื้อเดลี่

สถานการณ์

การวัดความแตกต่างของพื้นผิวระหว่างผลิตภัณฑ์เนื้อสัตว์สำเร็จรูปที่ได้รับการปรับโครงสร้าง

การวัดความแตกต่างของพื้นผิวระหว่างผลิตภัณฑ์เนื้อสัตว์สำเร็จรูปที่ได้รับการปรับโครงสร้าง

Deli Meat Firmness

Situation

Measuring the difference in texture between two restructured deli meat products.

Measuring the difference in texture between two restructured deli meat products.

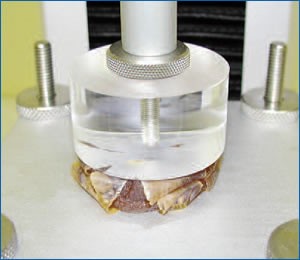

Potato Chips Hardness and Strength

Introduction

The following data was gathered for a potato chip processor, in an effort to come up with a consistent and objective way to evaluate their potato products, specifically its hardness. Current methods include mostly subjective, sensory testing. While sensory is important, it is subjective and varies from person to person.

The following data was gathered for a potato chip processor, in an effort to come up with a consistent and objective way to evaluate their potato products, specifically its hardness. Current methods include mostly subjective, sensory testing. While sensory is important, it is subjective and varies from person to person.

ความแข็งและความแข็งแรงของมันฝรั่งทอด

บทนำ

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับตัวประมวลผลมันฝรั่งในความพยายามที่จะหาวิธีที่สอดคล้องและมีวัตถุประสงค์ในการประเมินผลิตภัณฑ์มันฝรั่งของพวกเขาโดยเฉพาะความแข็ง วิธีการในปัจจุบัน ได้แก่ การทดสอบทางใจ ในขณะที่ประสาทสัมผัสเป็นสิ่งสำคัญมันเป็นเรื่องส่วนตัวและแตกต่างจากคนสู่คน

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับตัวประมวลผลมันฝรั่งในความพยายามที่จะหาวิธีที่สอดคล้องและมีวัตถุประสงค์ในการประเมินผลิตภัณฑ์มันฝรั่งของพวกเขาโดยเฉพาะความแข็ง วิธีการในปัจจุบัน ได้แก่ การทดสอบทางใจ ในขณะที่ประสาทสัมผัสเป็นสิ่งสำคัญมันเป็นเรื่องส่วนตัวและแตกต่างจากคนสู่คน

มีการประเมินตัวอย่างที่แตกต่างกันสามตัวอย่าง พวกเขามีดังนี้:

Rice White and Brown Rice Firmness

Situation

For most consumers, the option of white or brown rice comes down to a preference in texture versus a desire for the healthy option. The two varieties are very similar– white rice is produced from brown by the removal of the outer bran and germ layers – however, producers aim to increase the similarity in terms of mouthfeel by further processing techniques on the white variety.

For most consumers, the option of white or brown rice comes down to a preference in texture versus a desire for the healthy option. The two varieties are very similar– white rice is produced from brown by the removal of the outer bran and germ layers – however, producers aim to increase the similarity in terms of mouthfeel by further processing techniques on the white variety.

ความแน่นของข้าวขาวและข้าวกล้อง

สถานการณ์

สำหรับผู้บริโภคโดยส่วนมาก ทางเลือกของข้าวขาวและข้าวกล้องขึ้นอยู่กับความชอบด้านเนื้อสัมผัสและความต้องการในด้านสุขภาพ ข้าวทั้งสองประเภทมีความใกล้เคียงกันมาก คือข้าวขาวผลิตจากข้าวกล้องโดยการขัดสีชั้นรำข้าวและชั้นจมูกออก อย่างไรก็ตามผู้ผลิตมีเป้าหมายที่จะเพิ่มความคล้ายคลึงกันในแง่ของเนื้อสัมผัสโดยใช้เทคนิคในขบวนการผลิตที่เกี่ยวข้องกับข้าวขาวหลากหลายชนิด

สำหรับผู้บริโภคโดยส่วนมาก ทางเลือกของข้าวขาวและข้าวกล้องขึ้นอยู่กับความชอบด้านเนื้อสัมผัสและความต้องการในด้านสุขภาพ ข้าวทั้งสองประเภทมีความใกล้เคียงกันมาก คือข้าวขาวผลิตจากข้าวกล้องโดยการขัดสีชั้นรำข้าวและชั้นจมูกออก อย่างไรก็ตามผู้ผลิตมีเป้าหมายที่จะเพิ่มความคล้ายคลึงกันในแง่ของเนื้อสัมผัสโดยใช้เทคนิคในขบวนการผลิตที่เกี่ยวข้องกับข้าวขาวหลากหลายชนิด

Pasta Stickiness

Situation

Is well-cooked pasta the same as pasta that is cooked well? The elusive ‘al dente’ condition is a description relating to the firmness (or texture) of cooked pasta, but how sticky the product is also has a critical influence on the consumer’s perception of the perfect serving.

Is well-cooked pasta the same as pasta that is cooked well? The elusive ‘al dente’ condition is a description relating to the firmness (or texture) of cooked pasta, but how sticky the product is also has a critical influence on the consumer’s perception of the perfect serving.

การต้านทานแรงเฉือนของ Dog Hot

โปรเซสเซอร์ของฮอทดอกและผลิตภัณฑ์จากเนื้อสัตว์กำลังมองหาวิธีในการควบคุมเนื้อสัมผัสของผลิตภัณฑ์ได้ดีขึ้น วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

Hot Dog Shear Resistance

A processor of hot dogs and meat products was looking for a way to better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

Sliceability ของพริกไทย

สถานการณ์

เครื่องเตรียมอาหารขนาดใหญ่ต้องการวิธีการตรวจสอบคุณสมบัติการหั่นของส่วนผสมพริกไทยที่ยังไม่ผ่านกระบวนการก่อนที่จะหั่นผลิตภัณฑ์

เครื่องเตรียมอาหารขนาดใหญ่ต้องการวิธีการตรวจสอบคุณสมบัติการหั่นของส่วนผสมพริกไทยที่ยังไม่ผ่านกระบวนการก่อนที่จะหั่นผลิตภัณฑ์

หน่วยประมวลผลพบปัญหากับผลิตภัณฑ์ที่อ่อนเกินไปและจะทำให้เกิดการแบ่งส่วนข้อมูลในกระบวนการผลิต สิ่งนี้จะทำให้การหยุดทำงานที่สำคัญและผลกำไรลดลงในที่สุด

Pepperoni Sliceability

Situation

A large food processor needed a way to determine the slicing properties of its unprocessed pepperoni ingredient before the product was actually sliced.

A large food processor needed a way to determine the slicing properties of its unprocessed pepperoni ingredient before the product was actually sliced.

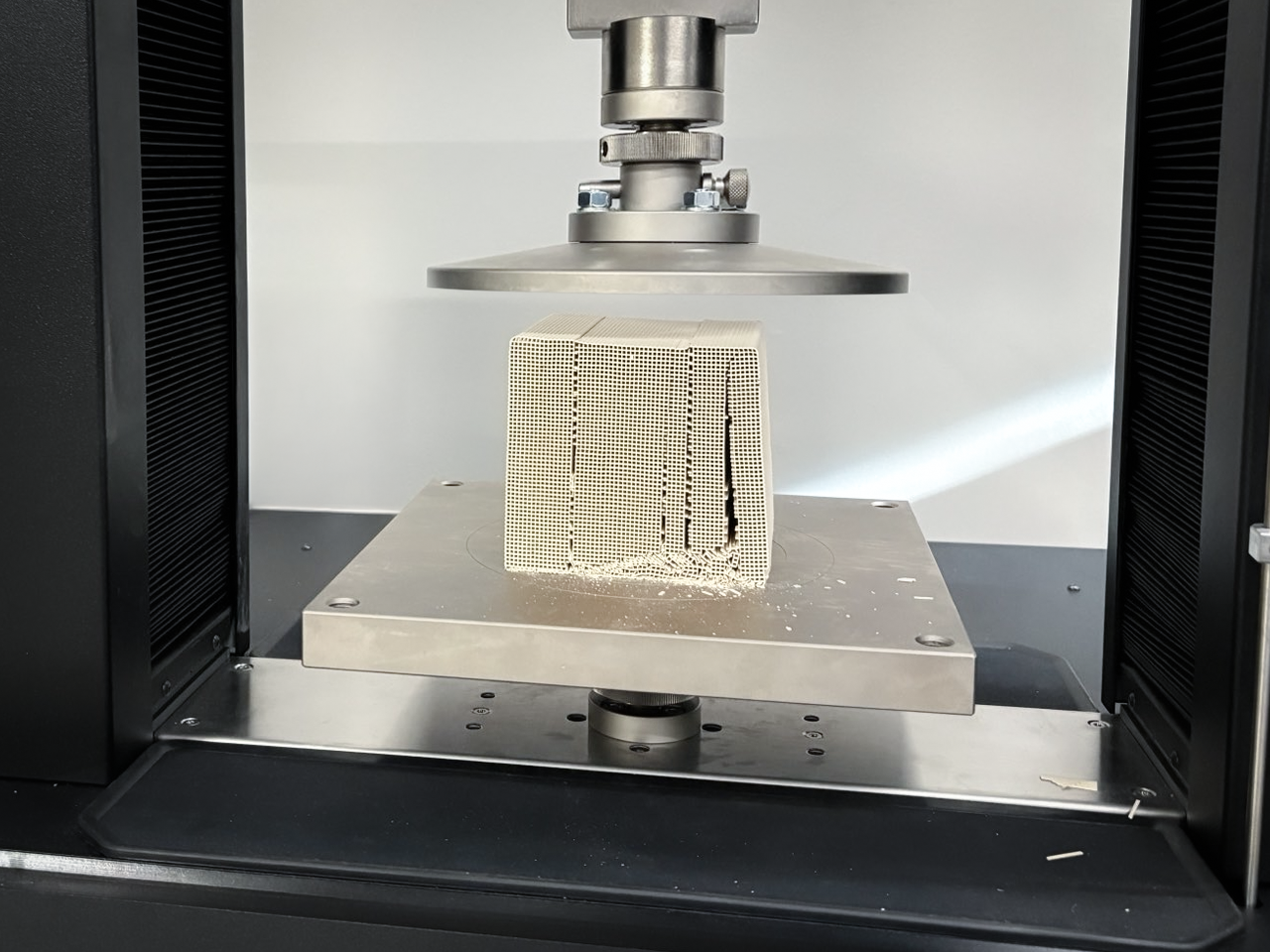

Sausage Ball Firmness

Situation

A processor of meat products was looking for a way to better control its outgoing product. Current methods involve simple visual inspections and are very subjective.

A processor of meat products was looking for a way to better control its outgoing product. Current methods involve simple visual inspections and are very subjective.

ไส้กรอกลูกแน่น

สถานการณ์

หน่วยประมวลผลของผลิตภัณฑ์จากเนื้อสัตว์กำลังมองหาวิธีที่จะควบคุมผลิตภัณฑ์ที่ส่งออกได้ดีขึ้น วิธีการในปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและเป็นอัตวิสัยมาก

หน่วยประมวลผลของผลิตภัณฑ์จากเนื้อสัตว์กำลังมองหาวิธีที่จะควบคุมผลิตภัณฑ์ที่ส่งออกได้ดีขึ้น วิธีการในปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและเป็นอัตวิสัยมาก

Chicken Patty Shear Resistance

Situation

A large processor of natural meat products was looking for a way to better control its outgoing product. Current methods involved a simple visual inspection and are very subjective.

A large processor of natural meat products was looking for a way to better control its outgoing product. Current methods involved a simple visual inspection and are very subjective.

ความต้านทานแรงเฉือนของขนมพายไก่

สถานการณ์

โปรเซสเซอร์ขนาดใหญ่ของผลิตภัณฑ์จากเนื้อสัตว์ธรรมชาติกำลังมองหาวิธีที่จะควบคุมผลิตภัณฑ์ที่ส่งออกได้ดีขึ้น วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพที่ง่ายและเป็นอัตวิสัยมาก

โปรเซสเซอร์ขนาดใหญ่ของผลิตภัณฑ์จากเนื้อสัตว์ธรรมชาติกำลังมองหาวิธีที่จะควบคุมผลิตภัณฑ์ที่ส่งออกได้ดีขึ้น วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพที่ง่ายและเป็นอัตวิสัยมาก

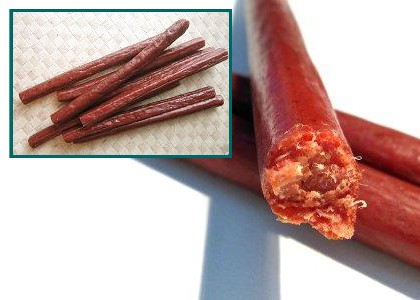

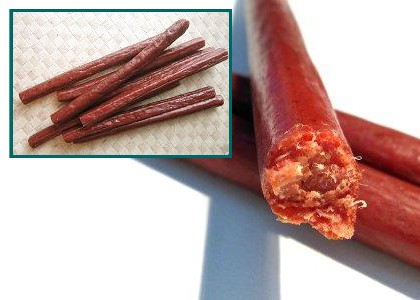

Beef Stick Firmness

Situation

A large manufacturer of beef sticks and beef jerky items was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

A large manufacturer of beef sticks and beef jerky items was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

เนื้อแน่นติดแน่น

สถานการณ์

ผู้ผลิตเนื้อวัวรายใหญ่และสินค้าประเภทเนื้อกระตุกกำลังมองหาวิธีการวัดเชิงปริมาณที่สม่ำเสมอในการวัดและควบคุมเนื้อสัมผัสของผลิตภัณฑ์ในที่สุด วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

ผู้ผลิตเนื้อวัวรายใหญ่และสินค้าประเภทเนื้อกระตุกกำลังมองหาวิธีการวัดเชิงปริมาณที่สม่ำเสมอในการวัดและควบคุมเนื้อสัมผัสของผลิตภัณฑ์ในที่สุด วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์

Fish Patty Hardness

Situation

A method to measure the hardness of fish cake patties was developed and applied as a predictor of process behaviour.

A method to measure the hardness of fish cake patties was developed and applied as a predictor of process behaviour.

ปลาแพตตี้ความแข็ง

สถานการณ์

วิธีการวัดความแข็งของไส้เค้กปลาได้รับการพัฒนาและนำไปใช้เป็นตัวทำนายพฤติกรรมของกระบวนการ

วิธีการวัดความแข็งของไส้เค้กปลาได้รับการพัฒนาและนำไปใช้เป็นตัวทำนายพฤติกรรมของกระบวนการ

ลูกค้ารายใหญ่ระบุเนื้อสัมผัสของเค้กปลาในระหว่างการผลิตเป็นจุดคุณภาพที่สำคัญ (CQP) ภายในกระบวนการผลิต พบปัญหาในระหว่างขั้นตอนการขึ้นรูปของการผลิตที่:

ความต้านทานแรงเฉือนของสุนัขร้อนเต้าหู้

สถานการณ์

ผู้แปรรูปเนื้อสัตว์ต้องการที่จะพัฒนาทางเลือกมังสวิรัติสำหรับฮอทดอกที่ได้รับความนิยมโดยใช้เต้าหู้ ต้องการความสัมพันธ์ที่ดีกับคุณสมบัติทางประสาทสัมผัสจากวิธีการใช้เครื่องมือ

ผู้แปรรูปเนื้อสัตว์ต้องการที่จะพัฒนาทางเลือกมังสวิรัติสำหรับฮอทดอกที่ได้รับความนิยมโดยใช้เต้าหู้ ต้องการความสัมพันธ์ที่ดีกับคุณสมบัติทางประสาทสัมผัสจากวิธีการใช้เครื่องมือ

Caviar Softness

Situation

A supplier of fresh fish products wanted an objective method that could reliably determine quality levels of the caviar throughout the harvesting season.

A supplier of fresh fish products wanted an objective method that could reliably determine quality levels of the caviar throughout the harvesting season.

คาเวียร์นุ่มนวล

สถานการณ์

ผู้จัดหาผลิตภัณฑ์ปลาสดต้องการวิธีการที่มีวัตถุประสงค์ซึ่งสามารถกำหนดระดับคุณภาพของคาเวียร์ได้อย่างน่าเชื่อถือตลอดฤดูเก็บเกี่ยว

ผู้จัดหาผลิตภัณฑ์ปลาสดต้องการวิธีการที่มีวัตถุประสงค์ซึ่งสามารถกำหนดระดับคุณภาพของคาเวียร์ได้อย่างน่าเชื่อถือตลอดฤดูเก็บเกี่ยว

Ground Meat Firmness

Situation

A large producer of cooked sausage products for the foodservice industry needed a way to measure the effect that changes in the raw product, as well as the grinding and cooking process had on the finished product texture.

A large producer of cooked sausage products for the foodservice industry needed a way to measure the effect that changes in the raw product, as well as the grinding and cooking process had on the finished product texture.

ความแน่นเนื้อดิน

สถานการณ์

ผู้ผลิตไส้กรอกผลิตภัณฑ์ปรุงสุกขนาดใหญ่สำหรับอุตสาหกรรมอาหารต้องการวิธีการวัดผลกระทบที่การเปลี่ยนแปลงของผลิตภัณฑ์ดิบเช่นเดียวกับกระบวนการบดและการปรุงอาหารที่มีต่อพื้นผิวของผลิตภัณฑ์สำเร็จรูป

ผู้ผลิตไส้กรอกผลิตภัณฑ์ปรุงสุกขนาดใหญ่สำหรับอุตสาหกรรมอาหารต้องการวิธีการวัดผลกระทบที่การเปลี่ยนแปลงของผลิตภัณฑ์ดิบเช่นเดียวกับกระบวนการบดและการปรุงอาหารที่มีต่อพื้นผิวของผลิตภัณฑ์สำเร็จรูป

Gelatin Snacks Regular and Sugar-Free

Situation

Sweeteners are under the spotlight in many foods, and choice of sweetener affects both taste and mouthfeel. To ensure a reformulation of an established product continues to meet consumer expectations, objective data are required. This may be very difficult as regards taste, but for mouthfeel, a food texture analyzer provides a reliable answer.

Sweeteners are under the spotlight in many foods, and choice of sweetener affects both taste and mouthfeel. To ensure a reformulation of an established product continues to meet consumer expectations, objective data are required. This may be very difficult as regards taste, but for mouthfeel, a food texture analyzer provides a reliable answer.

ขนมเจลาตินปกติและปราศจากน้ำตาล

สถานการณ์

สารให้ความหวานอยู่ภายใต้ความสนใจในอาหารหลายชนิดและการเลือกใช้สารให้ความหวานมีผลต่อทั้งรสชาติและปาก เพื่อให้มั่นใจว่ามีการปฏิรูปผลิตภัณฑ์ที่จัดตั้งขึ้นอย่างต่อเนื่องเพื่อตอบสนองความคาดหวังของผู้บริโภคจำเป็นต้องมีข้อมูลวัตถุประสงค์ นี่อาจเป็นเรื่องยากมากเมื่อพิจารณาถึงรสชาติ แต่สำหรับปากรู้สึกว่าเครื่องวิเคราะห์เนื้อสัมผัสอาหารให้คำตอบที่เชื่อถือได้ ในตัวอย่างนี้เราเปรียบเทียบขนมเจลาตินที่ผสมกับ HFCS (น้ำเชื่อมข

สารให้ความหวานอยู่ภายใต้ความสนใจในอาหารหลายชนิดและการเลือกใช้สารให้ความหวานมีผลต่อทั้งรสชาติและปาก เพื่อให้มั่นใจว่ามีการปฏิรูปผลิตภัณฑ์ที่จัดตั้งขึ้นอย่างต่อเนื่องเพื่อตอบสนองความคาดหวังของผู้บริโภคจำเป็นต้องมีข้อมูลวัตถุประสงค์ นี่อาจเป็นเรื่องยากมากเมื่อพิจารณาถึงรสชาติ แต่สำหรับปากรู้สึกว่าเครื่องวิเคราะห์เนื้อสัมผัสอาหารให้คำตอบที่เชื่อถือได้ ในตัวอย่างนี้เราเปรียบเทียบขนมเจลาตินที่ผสมกับ HFCS (น้ำเชื่อมข

Carrageenan Penetration Strength

Customer

A Hydrocolloids manufacturer wanted to measure the functional properties of their gel systems. Results were used during the development of customer blends and quality-based analysis.

Carrageenan Penetration Strength

ลูกค้า

ผู้ผลิตไฮโดรคอลลอยด์ต้องการวัดคุณสมบัติการทำงานของระบบเจล ผลลัพธ์ถูกนำมาใช้ในระหว่างการพัฒนาส่วนผสมของลูกค้าและการวิเคราะห์เชิงคุณภาพ

ผู้ผลิตไฮโดรคอลลอยด์ต้องการวัดคุณสมบัติการทำงานของระบบเจล ผลลัพธ์ถูกนำมาใช้ในระหว่างการพัฒนาส่วนผสมของลูกค้าและการวิเคราะห์เชิงคุณภาพ

Cocktail Sausage Firmness Comparison

Situation

The following data was gathered for a potential client, in an effort to come up with a more consistent and objective way to evaluate the texture of their sausage products, specifically the firmness of the products. The current method is mostly on a sensory basis and can be very subjective.

The following data was gathered for a potential client, in an effort to come up with a more consistent and objective way to evaluate the texture of their sausage products, specifically the firmness of the products. The current method is mostly on a sensory basis and can be very subjective.

การเปรียบเทียบความหนาแน่นของไส้กรอกค็อกเทล

สถานการณ์

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับลูกค้าที่มีศักยภาพในความพยายามที่จะหาวิธีที่สอดคล้องและมีวัตถุประสงค์เพื่อประเมินพื้นผิวของผลิตภัณฑ์ไส้กรอกของพวกเขาโดยเฉพาะความแน่นเนื้อของผลิตภัณฑ์ วิธีการในปัจจุบันส่วนใหญ่อยู่บนพื้นฐานทางประสาทสัมผัสและอาจเป็นอัตนัย ในขณะที่ประสาทสัมผัสเป็นสิ่งสำคัญมันสามารถแตกต่างกันอย่างมีนัยสำคัญจากคนสู่คน

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับลูกค้าที่มีศักยภาพในความพยายามที่จะหาวิธีที่สอดคล้องและมีวัตถุประสงค์เพื่อประเมินพื้นผิวของผลิตภัณฑ์ไส้กรอกของพวกเขาโดยเฉพาะความแน่นเนื้อของผลิตภัณฑ์ วิธีการในปัจจุบันส่วนใหญ่อยู่บนพื้นฐานทางประสาทสัมผัสและอาจเป็นอัตนัย ในขณะที่ประสาทสัมผัสเป็นสิ่งสำคัญมันสามารถแตกต่างกันอย่างมีนัยสำคัญจากคนสู่คน

Salami Firmness

Situation

Meats contain mostly muscle (with directional fibers) plus fat, which will vary from cut to cut, making it a non-homogenous foodstuff in it most natural form.

Meats contain mostly muscle (with directional fibers) plus fat, which will vary from cut to cut, making it a non-homogenous foodstuff in it most natural form.

ความแน่นของซาลามี่

สถานการณ์

เนื้อสัตว์ส่วนใหญ่มีกล้ามเนื้อ (มีเส้นใยกำกับทิศทาง) บวกกับไขมันซึ่งจะแตกต่างกันไปตามการตัดทำให้เป็นอาหารที่ไม่เหมือนกันในรูปแบบที่เป็นธรรมชาติมากที่สุด ผลิตภัณฑ์จากเนื้อสัตว์ที่สร้างใหม่เช่นซาลามี่อาจประกอบด้วยส่วนผสมจากเนื้อสัตว์ที่แตกต่างกันรวมถึงไขมันและสารเติมแต่งอื่

เนื้อสัตว์ส่วนใหญ่มีกล้ามเนื้อ (มีเส้นใยกำกับทิศทาง) บวกกับไขมันซึ่งจะแตกต่างกันไปตามการตัดทำให้เป็นอาหารที่ไม่เหมือนกันในรูปแบบที่เป็นธรรมชาติมากที่สุด ผลิตภัณฑ์จากเนื้อสัตว์ที่สร้างใหม่เช่นซาลามี่อาจประกอบด้วยส่วนผสมจากเนื้อสัตว์ที่แตกต่างกันรวมถึงไขมันและสารเติมแต่งอื่

การคัดเกรดมันฝรั่งสำหรับสลัด

ใบสมัคร

การวัดพื้นผิวของมันฝรั่งหั่นสี่เหลี่ยมลูกเต๋าที่ใช้ในสลัดมันฝรั่ง

ปัญหา

หน่วยประมวลผลของมันฝรั่งหั่นสี่เหลี่ยมลูกเต๋านั้นขึ้นอยู่กับผลลัพธ์ทางประสาทสัมผัสที่ไม่สอดคล้องกันและอัตนัยในการวัดพื้นผิวของผลิตภัณฑ์ของพวกเขา ดังนั้นพวกเขาจึงต้องการวิธีการวัดปริมาณที่สม่ำเสมอและทำซ้ำได้ในการวัดผลิตภัณฑ์ของพวกเขาและใช้ผลิตภัณฑ์ 'อุดมคติ' ที่เป็นมาตรฐาน

สารละลาย

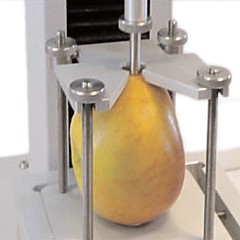

Apple Freshness Comparison

Application

Measuring ripeness and firmness of fresh apples.

Measuring ripeness and firmness of fresh apples.

Problem

This processor did not have a way to objectively or quantitatively measure the texture of their products. Current methods for evaluating ripeness and firmness of apples were done through sensory panel testing and use of a penetrometer which both gave inconsistent and unreliable data.

การเปรียบเทียบความสดใหม่ของ Apple

ใบสมัคร

การวัดความสุกและความแน่นของแอปเปิ้ลสด

การวัดความสุกและความแน่นของแอปเปิ้ลสด

ปัญหา

โปรเซสเซอร์นี้ไม่มีวิธีวัดปริมาณเนื้อสัมผัสของผลิตภัณฑ์ วิธีการในปัจจุบันสำหรับการประเมินความสุกและความแน่นของแอปเปิ้ลทำผ่านการทดสอบทางประสาทสัมผัสและการใช้เครื่องวัดความขุ่นซึ่งทั้งคู่ให้ข้อมูลที่ไม่สอดคล้องและไม่น่าเชื่อถือ

Carrots (Canned) Firmness

Introduction

The following customer data was gathered in an effort to develop a more objective way to evaluate the texture – firmness - of canned carrots in their final form. Currently, the processor relied on a subjective assessment. The ultimate goal of this method would be the ability to correlate objective numbers to the subjective sensory data and make recommendations for packaging and canning.

The following customer data was gathered in an effort to develop a more objective way to evaluate the texture – firmness - of canned carrots in their final form. Currently, the processor relied on a subjective assessment. The ultimate goal of this method would be the ability to correlate objective numbers to the subjective sensory data and make recommendations for packaging and canning.

ความแน่นของแครอท (กระป๋อง)

บทนำ

ข้อมูลลูกค้าต่อไปนี้ถูกรวบรวมในความพยายามที่จะพัฒนาวิธีการที่มีวัตถุประสงค์มากขึ้นในการประเมินพื้นผิว - ความแน่น - ของแครอทกระป๋องในรูปแบบสุดท้ายของพวกเขา ปัจจุบันโปรเซสเซอร์ใช้การประเมินแบบอัตนัย เป้าหมายสูงสุดของวิธีนี้คือความสามารถในการเชื่อมโยงหมายเลขวัตถุประสงค์กับข้อมูลทางประสาทสัมผัสส่วนตัวและให้คำแนะนำสำหรับบรรจุภัณฑ์และบรรจุกระป๋อง

ข้อมูลลูกค้าต่อไปนี้ถูกรวบรวมในความพยายามที่จะพัฒนาวิธีการที่มีวัตถุประสงค์มากขึ้นในการประเมินพื้นผิว - ความแน่น - ของแครอทกระป๋องในรูปแบบสุดท้ายของพวกเขา ปัจจุบันโปรเซสเซอร์ใช้การประเมินแบบอัตนัย เป้าหมายสูงสุดของวิธีนี้คือความสามารถในการเชื่อมโยงหมายเลขวัตถุประสงค์กับข้อมูลทางประสาทสัมผัสส่วนตัวและให้คำแนะนำสำหรับบรรจุภัณฑ์และบรรจุกระป๋อง

วัสดุและวิธีการ

Potato softness grading for salad

Application

Measuring texture of diced potatoes used in potato salads.

Problem

A processor of diced potatoes was relying on inconsistent, subjective sensory results to measure the texture of their product. Therefore, they needed a quantifiable, consistent and repeatable way to measure their product and implement a standardized range of 'ideal' product.

Solution

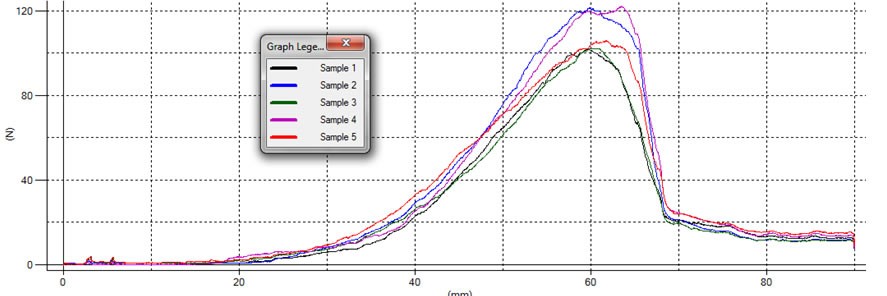

มะเขือเทศ (หั่นสี่เหลี่ยมลูกเต๋าบรรจุกระป๋อง)

ใบสมัคร

เพื่อวัดความแน่นเนื้อโดยรวมของมะเขือเทศกระป๋องและหั่นสี่เหลี่ยมลูกเต๋า

เพื่อวัดความแน่นเนื้อโดยรวมของมะเขือเทศกระป๋องและหั่นสี่เหลี่ยมลูกเต๋า

ปัญหา

หน่วยประมวลผลของผักกระป๋องรวมถึงมะเขือเทศหั่นสี่เหลี่ยมลูกเต๋าไม่มีวัตถุประสงค์ที่สอดคล้องและทำซ้ำได้ในการวัดความแน่นของมะเขือเทศกระป๋องหรือพัฒนามาตรฐานเพื่อเปรียบเทียบผลิตภัณฑ์อื่น ๆ ทั้งหมด

การเตรียมตัวอย่าง

มะเขือเทศระบายหมดแล้วใส่ลงในเซลล์ทดสอบจนกว่าเซลล์ทดสอบจะเต็ม จำนวนนั้นชั่งเป็นกรัม กลุ่มตัวอย่างมีน้ำหนักตั้งแต่ 204-205 กรัม

Tomatoes (Canned Diced) Bulk Firmness

Application

To measure overall firmness of canned, diced tomatoes.

To measure overall firmness of canned, diced tomatoes.

Problem

A processor of canned vegetables, including diced tomatoes, did not have an objective, consistent, repeatable way to measure the firmness of the canned tomatoes nor develop a standard to which to compare all other products.

Perogie Mixture Filling Consistency

Application

One sample of perogie (or pierogi) filling was sent for preliminary evaluation. This sample is representative of the whole line of products; therefore these methods can be applied to the full range of products produced.

One sample of perogie (or pierogi) filling was sent for preliminary evaluation. This sample is representative of the whole line of products; therefore these methods can be applied to the full range of products produced.

การเติมส่วนผสมของ Perogie อย่างสม่ำเสมอ

ใบสมัคร

ตัวอย่างหนึ่งของการบรรจุ Perogie (หรือ Pierogi) ถูกส่งไปประเมินเบื้องต้น ตัวอย่างนี้เป็นตัวแทนของสายผลิตภัณฑ์ทั้งหมด ดังนั้นวิธีการเหล่านี้สามารถนำไปใช้กับผลิตภัณฑ์ที่ผลิตเต็มรูปแบบ

ตัวอย่างหนึ่งของการบรรจุ Perogie (หรือ Pierogi) ถูกส่งไปประเมินเบื้องต้น ตัวอย่างนี้เป็นตัวแทนของสายผลิตภัณฑ์ทั้งหมด ดังนั้นวิธีการเหล่านี้สามารถนำไปใช้กับผลิตภัณฑ์ที่ผลิตเต็มรูปแบบ

Cranberry Bulk Firmness

Application

A processor of cranberries wanted a way to determine how to process individual lots based on the texture of the fresh product. Firmer cranberries are typically better suited for one type of products while the softer ones work better for another.

A processor of cranberries wanted a way to determine how to process individual lots based on the texture of the fresh product. Firmer cranberries are typically better suited for one type of products while the softer ones work better for another.

ความแน่นของแครนเบอร์รี่

ใบสมัคร

หน่วยประมวลผลของแครนเบอร์รี่ต้องการวิธีในการกำหนดวิธีการประมวลผลล็อตของแต่ละบุคคลตามพื้นผิวของผลิตภัณฑ์สด โดยทั่วไปแล้วแครนเบอร์รี่ Firmer นั้นจะเหมาะสมกว่าสำหรับผลิตภัณฑ์ประเภทหนึ่งในขณะที่ผลิตภัณฑ์ที่นุ่มกว่าจะทำงานได้ดีกว่าสำหรับผลิตภัณฑ์อื่น

หน่วยประมวลผลของแครนเบอร์รี่ต้องการวิธีในการกำหนดวิธีการประมวลผลล็อตของแต่ละบุคคลตามพื้นผิวของผลิตภัณฑ์สด โดยทั่วไปแล้วแครนเบอร์รี่ Firmer นั้นจะเหมาะสมกว่าสำหรับผลิตภัณฑ์ประเภทหนึ่งในขณะที่ผลิตภัณฑ์ที่นุ่มกว่าจะทำงานได้ดีกว่าสำหรับผลิตภัณฑ์อื่น

Baked Beans Bulk Firmness

Application

A large processor of several different varieties of baked beans was looking for a way to supplement their current sensory methods. While these subjective methods are important to the company, a more objective method would add extra validation to the information already gathered from panels.

A large processor of several different varieties of baked beans was looking for a way to supplement their current sensory methods. While these subjective methods are important to the company, a more objective method would add extra validation to the information already gathered from panels.

อบถั่วความแน่นเป็นกลุ่ม

ใบสมัคร

โปรเซสเซอร์ขนาดใหญ่ที่มีถั่วอบหลากหลายพันธุ์กำลังมองหาวิธีการเสริมวิธีการทางประสาทสัมผัสในปัจจุบัน ในขณะที่วิธีการอัตนัยเหล่านี้มีความสำคัญต่อ บริษัท แต่วิธีการที่เป็นเป้าหมายมากขึ้นจะเพิ่มการตรวจสอบความถูกต้องเพิ่มเติมให้กับข้อมูลที่รวบรวมจากแผงควบคุม

โปรเซสเซอร์ขนาดใหญ่ที่มีถั่วอบหลากหลายพันธุ์กำลังมองหาวิธีการเสริมวิธีการทางประสาทสัมผัสในปัจจุบัน ในขณะที่วิธีการอัตนัยเหล่านี้มีความสำคัญต่อ บริษัท แต่วิธีการที่เป็นเป้าหมายมากขึ้นจะเพิ่มการตรวจสอบความถูกต้องเพิ่มเติมให้กับข้อมูลที่รวบรวมจากแผงควบคุม

Peaches (Canned) Firmness

Application

To measure overall firmness of canned peaches in order to determine differences between different batches of product.

To measure overall firmness of canned peaches in order to determine differences between different batches of product.

ความแน่นของลูกพีช (กระป๋อง)

ใบสมัคร

เพื่อวัดความแน่นโดยรวมของลูกพีชบรรจุกระป๋องเพื่อกำหนดความแตกต่างระหว่างแบตช์ที่แตกต่างกันของผลิตภัณฑ์

เพื่อวัดความแน่นโดยรวมของลูกพีชบรรจุกระป๋องเพื่อกำหนดความแตกต่างระหว่างแบตช์ที่แตกต่างกันของผลิตภัณฑ์

Avocado - Frozen Product Firmness

Situation

Have you ever tried sorting frozen avocado? After dicing, soft avocado is suitable as a vacuum packed salad, whereas the firmer product is further processed as a higher-priced dried product. Wouldn’t it be great if a machine test could reliably do this for you?

Have you ever tried sorting frozen avocado? After dicing, soft avocado is suitable as a vacuum packed salad, whereas the firmer product is further processed as a higher-priced dried product. Wouldn’t it be great if a machine test could reliably do this for you?

Presented with three sample batches, FTC was able to demonstrate a method to precisely apply a repeatable firmness test.

อะโวคาโด - ความแน่นของผลิตภัณฑ์แช่แข็ง

สถานการณ์

คุณเคยลองจัดเรียงอะโวคาโดแช่แข็งหรือไม่? อะโวคาโดนุ่มเหมาะสำหรับเป็นสลัดบรรจุสูญญากาศในขณะที่ผลิตภัณฑ์กระชับจะถูกประมวลผลเพิ่มเติมเป็นผลิตภัณฑ์แห้งราคาสูงกว่า จะดีหรือไม่ถ้าการทดสอบเครื่องจักรทำได้อย่างน่าเชื่อถือสำหรับคุณ

คุณเคยลองจัดเรียงอะโวคาโดแช่แข็งหรือไม่? อะโวคาโดนุ่มเหมาะสำหรับเป็นสลัดบรรจุสูญญากาศในขณะที่ผลิตภัณฑ์กระชับจะถูกประมวลผลเพิ่มเติมเป็นผลิตภัณฑ์แห้งราคาสูงกว่า จะดีหรือไม่ถ้าการทดสอบเครื่องจักรทำได้อย่างน่าเชื่อถือสำหรับคุณ

นำเสนอด้วยกลุ่มตัวอย่างสามชุด FTC สามารถแสดงให้เห็นถึงวิธีการทดสอบความแน่นแบบใช้ซ้ำได้อย่างแม่นยำ

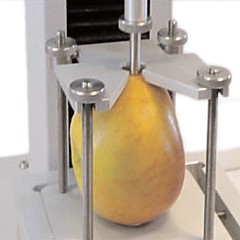

Apple Breeding Trials and Ripeness

Customer

Horticulture Research Station wanted a precision penetrometer for hardness testing of different varieties of apple during plant breeding trials. Flexibility for future test configurations were also a requirement.

Horticulture Research Station wanted a precision penetrometer for hardness testing of different varieties of apple during plant breeding trials. Flexibility for future test configurations were also a requirement.

Problem

Textural properties and structure of different varieties of apple were identified as critical sensory characteristics. Changes in these properties needed to be monitored during plant breeding work.

การทดลองและผสมพันธุ์ของ Apple

ลูกค้า

สถานีวิจัยการปลูกพืชสวนต้องการเครื่องเจาะทะลุที่แม่นยำสำหรับการทดสอบความแข็งของแอปเปิลพันธุ์ต่างๆในระหว่างการทดลองเพาะพันธุ์พืช ความยืดหยุ่นสำหรับการกำหนดค่าการทดสอบในอนาคตก็เป็นข้อกำหนดเช่นกัน

สถานีวิจัยการปลูกพืชสวนต้องการเครื่องเจาะทะลุที่แม่นยำสำหรับการทดสอบความแข็งของแอปเปิลพันธุ์ต่างๆในระหว่างการทดลองเพาะพันธุ์พืช ความยืดหยุ่นสำหรับการกำหนดค่าการทดสอบในอนาคตก็เป็นข้อกำหนดเช่นกัน

ปัญหา

คุณสมบัติทางเนื้อสัมผัสและโครงสร้างของแอปเปิ้ลพันธุ์ต่าง ๆ ถูกระบุว่าเป็นลักษณะทางประสาทสัมผัสที่สำคัญ การเปลี่ยนแปลงคุณสมบัติเหล่านี้จำเป็นต้องได้รับการตรวจสอบในระหว่างการปรับปรุงพันธุ์พืช

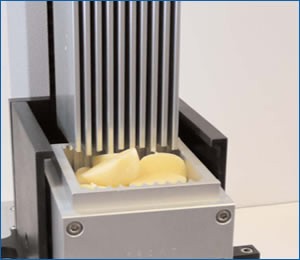

Potato Firmness for Dicing and Cooking Profile

Customer

Ready-prepared salad manufacturer required simple and reproducible method of measuring the texture of diced potato used in the production of chilled salad.

Ready-prepared salad manufacturer required simple and reproducible method of measuring the texture of diced potato used in the production of chilled salad.

ความแน่วแน่ของมันฝรั่งสำหรับการทำแบบลูกเต๋าและทำอาหาร

ลูกค้า

ผู้ผลิตสลัดพร้อมปรุงต้องใช้วิธีการที่เรียบง่ายและทำซ้ำได้ในการวัดพื้นผิวของมันฝรั่งหั่นสี่เหลี่ยมลูกเต๋าที่ใช้ในการผลิตสลัดแช่เย็น

ผู้ผลิตสลัดพร้อมปรุงต้องใช้วิธีการที่เรียบง่ายและทำซ้ำได้ในการวัดพื้นผิวของมันฝรั่งหั่นสี่เหลี่ยมลูกเต๋าที่ใช้ในการผลิตสลัดแช่เย็น

ปัญหา

การแปรผันของเนื้อสัมผัสและความสม่ำเสมอของมันฝรั่งปรุงสุกจากซัพพลายเออร์ภายในและภายนอก มันฝรั่งนั้นแข็งและแข็งเกินไปหรือนิ่มเกินไปและร่วน

การแปรผันของเนื้อสัมผัสและความสม่ำเสมอของมันฝรั่งปรุงสุกจากซัพพลายเออร์ภายในและภายนอก มันฝรั่งนั้นแข็งและแข็งเกินไปหรือนิ่มเกินไปและร่วน

Date Firmness and Ripeness

The quality of fresh dates was determined using a compression test in conjunction with a specialized test table.

The quality of fresh dates was determined using a compression test in conjunction with a specialized test table.

วันที่ความแน่นและความริบหรี่

คุณภาพของวันที่สดใหม่ถูกกำหนดโดยใช้การทดสอบการบีบอัดร่วมกับตารางทดสอบพิเศษ

คุณภาพของวันที่สดใหม่ถูกกำหนดโดยใช้การทดสอบการบีบอัดร่วมกับตารางทดสอบพิเศษ

ความต้องการ

ผู้จัดหาวันที่ต้องการวิธีที่ง่ายและเชื่อถือได้ในการกำหนดคุณภาพของวันที่สดใหม่โดยไม่ต้องลบหลุมก่อน คุณสมบัติของพื้นผิวของผลิตภัณฑ์พบว่าเป็นคุณลักษณะที่สำคัญในการกำหนดคุณภาพ

ผู้จัดหาวันที่ต้องการวิธีที่ง่ายและเชื่อถือได้ในการกำหนดคุณภาพของวันที่สดใหม่โดยไม่ต้องลบหลุมก่อน คุณสมบัติของพื้นผิวของผลิตภัณฑ์พบว่าเป็นคุณลักษณะที่สำคัญในการกำหนดคุณภาพ

Cream Cheese Firmness

Situation

A dairy foods processor wanted a quantifiable, consistent way to detect differences between two cream cheese products.

A dairy foods processor wanted a quantifiable, consistent way to detect differences between two cream cheese products.

This processor had just formulated a new, low-fat cream cheese product and needed a way to measure the effects on its texture from changing the formulation from regular to low-fat.

ครีมชีสเฟิร์ม

สถานการณ์

ผู้แปรรูปผลิตภัณฑ์นมต้องการวิธีที่สามารถวัดปริมาณได้และสม่ำเสมอในการตรวจสอบความแตกต่างระหว่างผลิตภัณฑ์ครีมชีสสองรายการ

ผู้แปรรูปผลิตภัณฑ์นมต้องการวิธีที่สามารถวัดปริมาณได้และสม่ำเสมอในการตรวจสอบความแตกต่างระหว่างผลิตภัณฑ์ครีมชีสสองรายการ

หน่วยประมวลผลนี้เพิ่งคิดค้นสูตรผลิตภัณฑ์ครีมชีสไขมันต่ำใหม่และต้องการวิธีการวัดผลกระทบที่มีต่อเนื้อสัมผัสจากการเปลี่ยนสูตรจากปกติเป็นไขมันต่ำ

Cheese Slices Firmness and Stickiness

Situation

This processor did not have a way to objectively measure the difference in texture between their processed, sliced cheese products which they knew had two different textures by having peformed sensory testing on the products. If the cheese is too soft, it clogs up the industrial slicers. If the cheese is too hard, it will not be a desirable end product for consumer.

This processor did not have a way to objectively measure the difference in texture between their processed, sliced cheese products which they knew had two different textures by having peformed sensory testing on the products. If the cheese is too soft, it clogs up the industrial slicers. If the cheese is too hard, it will not be a desirable end product for consumer.

ชิ้นชีสความแน่นและเหนียว

สถานการณ์

หน่วยประมวลผลนี้ไม่มีวิธีวัดความแตกต่างของเนื้อสัมผัสระหว่างผลิตภัณฑ์ชีสที่ผ่านการแปรรูปและหั่นบาง ๆ อย่างเป็นรูปธรรมซึ่งพวกเขารู้ว่ามีพื้นผิวที่แตกต่างกันสองแบบโดยทำการทดสอบทางประสาทสัมผัสกับผลิตภัณฑ์ หากชีสนิ่มเกินไปมันจะอุดตันตัวแบ่งส่วนข้อมูลอุตสาหกรรม หากชีสแข็งเกินไปมันจะไม่เป็นผลิตภัณฑ์ที่ต้องการสำหรับผู้บริโภค

หน่วยประมวลผลนี้ไม่มีวิธีวัดความแตกต่างของเนื้อสัมผัสระหว่างผลิตภัณฑ์ชีสที่ผ่านการแปรรูปและหั่นบาง ๆ อย่างเป็นรูปธรรมซึ่งพวกเขารู้ว่ามีพื้นผิวที่แตกต่างกันสองแบบโดยทำการทดสอบทางประสาทสัมผัสกับผลิตภัณฑ์ หากชีสนิ่มเกินไปมันจะอุดตันตัวแบ่งส่วนข้อมูลอุตสาหกรรม หากชีสแข็งเกินไปมันจะไม่เป็นผลิตภัณฑ์ที่ต้องการสำหรับผู้บริโภค

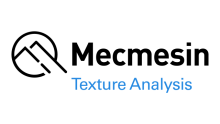

Parmesan Cheese Fracturability

Situation

Measuring fracturability and cohesiveness of Parmesan cheese blocks in order to predict if the cheese will shred well or not.

Measuring fracturability and cohesiveness of Parmesan cheese blocks in order to predict if the cheese will shred well or not.

Parmesan Cheese Fracturability

สถานการณ์

การวัดความเปราะบางและการเกาะติดกันของบล็อกพาเมซานชีสเพื่อทำนายว่าชีสจะฉีกขาดได้ดีหรือไม่

การวัดความเปราะบางและการเกาะติดกันของบล็อกพาเมซานชีสเพื่อทำนายว่าชีสจะฉีกขาดได้ดีหรือไม่

Mushrooms (Canned) Firmness Effect of Salt

Situation

A producer of canned mushrooms uses simple subjective measurements to evaluate the final texture of their product. The information is often used to make adjustments to the process. Their real need, however, is to obtain objective data that represents the sensory evaluation. Our example here demonstrates how this can easily be done using a food texture analyzer. For the particular test, an unsalted (control) product and a low-salt equivalent were compared.

A producer of canned mushrooms uses simple subjective measurements to evaluate the final texture of their product. The information is often used to make adjustments to the process. Their real need, however, is to obtain objective data that represents the sensory evaluation. Our example here demonstrates how this can easily be done using a food texture analyzer. For the particular test, an unsalted (control) product and a low-salt equivalent were compared.

เห็ด (บรรจุกระป๋อง) ความแน่นผลของเกลือ

สถานการณ์

ผู้ผลิตเห็ดกระป๋องใช้การวัดอัตนัยง่ายๆเพื่อประเมินเนื้อสัมผัสสุดท้ายของผลิตภัณฑ์ ข้อมูลมักถูกใช้เพื่อทำการปรับเปลี่ยนกระบวนการ อย่างไรก็ตามความต้องการที่แท้จริงของพวกเขาคือการได้รับข้อมูลวัตถุประสงค์ที่แสดงถึงการประเมินทางประสาทสัมผัส ตัวอย่างของเราที่นี่แสดงให้เห็นถึงวิธีการนี้สามารถทำได้อย่างง่ายดายโดยใช้เครื่องวิเคราะห์เนื้อสัมผัสอาหาร สำหรับการทดสอบโดยเฉพาะผลิตภัณฑ์เปรียบเทียบ (เกลือ) และไม่เทียบเท่าเกลือต่ำ

ผู้ผลิตเห็ดกระป๋องใช้การวัดอัตนัยง่ายๆเพื่อประเมินเนื้อสัมผัสสุดท้ายของผลิตภัณฑ์ ข้อมูลมักถูกใช้เพื่อทำการปรับเปลี่ยนกระบวนการ อย่างไรก็ตามความต้องการที่แท้จริงของพวกเขาคือการได้รับข้อมูลวัตถุประสงค์ที่แสดงถึงการประเมินทางประสาทสัมผัส ตัวอย่างของเราที่นี่แสดงให้เห็นถึงวิธีการนี้สามารถทำได้อย่างง่ายดายโดยใช้เครื่องวิเคราะห์เนื้อสัมผัสอาหาร สำหรับการทดสอบโดยเฉพาะผลิตภัณฑ์เปรียบเทียบ (เกลือ) และไม่เทียบเท่าเกลือต่ำ

Pickled Gherkin Crunchiness

Situation

If you want to know the crunchiness of a pickle: bite it. Expert testers are relied on throughout the food industry, but can you objectively quantify crunchiness, and use this to assure product consistency, or improve manufacture? Different preparations can also be compared for measurable degrees of crunchiness.

If you want to know the crunchiness of a pickle: bite it. Expert testers are relied on throughout the food industry, but can you objectively quantify crunchiness, and use this to assure product consistency, or improve manufacture? Different preparations can also be compared for measurable degrees of crunchiness.

Gherkin ดอง

สถานการณ์

หากคุณต้องการทราบความกรุบกรอบของผักดอง: กัดมัน ผู้ทดสอบที่มีความเชี่ยวชาญนั้นอาศัยในอุตสาหกรรมอาหารทั้งหมด แต่คุณสามารถวัดปริมาณความเป็น crunchiness และใช้สิ่งนี้เพื่อรับรองความสอดคล้องของผลิตภัณฑ์หรือปรับปรุงการผลิตได้หรือไม่? การเตรียมการที่แตกต่างกันยังสามารถนำมาเปรียบเทียบกับระดับของความกรุบกรอบที่วัดได้

หากคุณต้องการทราบความกรุบกรอบของผักดอง: กัดมัน ผู้ทดสอบที่มีความเชี่ยวชาญนั้นอาศัยในอุตสาหกรรมอาหารทั้งหมด แต่คุณสามารถวัดปริมาณความเป็น crunchiness และใช้สิ่งนี้เพื่อรับรองความสอดคล้องของผลิตภัณฑ์หรือปรับปรุงการผลิตได้หรือไม่? การเตรียมการที่แตกต่างกันยังสามารถนำมาเปรียบเทียบกับระดับของความกรุบกรอบที่วัดได้

Butter vs Margarine Texture Analysis

Situation

Margarine was developed to be a lower fat replacement for butter. To be successful in this goal, it is important that the two have similar textural properties as well as flavor and color.

Margarine was developed to be a lower fat replacement for butter. To be successful in this goal, it is important that the two have similar textural properties as well as flavor and color.

การวิเคราะห์เนื้อเนยกับเนยเทียม

สถานการณ์

เนยเทียมได้รับการพัฒนาให้เป็นไขมันทดแทนที่ต่ำกว่าสำหรับเนย การประสบความสำเร็จในเป้าหมายนี้เป็นสิ่งสำคัญที่ทั้งสองมีคุณสมบัติด้านเนื้อสัมผัสที่คล้ายคลึงกันรวมถึงรสชาติและสี

เนยเทียมได้รับการพัฒนาให้เป็นไขมันทดแทนที่ต่ำกว่าสำหรับเนย การประสบความสำเร็จในเป้าหมายนี้เป็นสิ่งสำคัญที่ทั้งสองมีคุณสมบัติด้านเนื้อสัมผัสที่คล้ายคลึงกันรวมถึงรสชาติและสี

Cottage Cheese Curd Firmness

Situation

Dairy companies need a way to consistently measure and therefore, control the textural attributes of cottage cheese curd. Consumer desires for the texture of this product can vary considerably by geographical locations.

Dairy companies need a way to consistently measure and therefore, control the textural attributes of cottage cheese curd. Consumer desires for the texture of this product can vary considerably by geographical locations.

ความแน่นของคอทเทจชีส

สถานการณ์

บริษัท ผลิตนมต้องการวิธีในการวัดอย่างสม่ำเสมอดังนั้นควบคุมคุณลักษณะของเนื้อของเต้าหู้ชีส ความต้องการของผู้บริโภคสำหรับพื้นผิวของผลิตภัณฑ์นี้อาจแตกต่างกันมากตามสถานที่ตั้งทางภูมิศาสตร์

บริษัท ผลิตนมต้องการวิธีในการวัดอย่างสม่ำเสมอดังนั้นควบคุมคุณลักษณะของเนื้อของเต้าหู้ชีส ความต้องการของผู้บริโภคสำหรับพื้นผิวของผลิตภัณฑ์นี้อาจแตกต่างกันมากตามสถานที่ตั้งทางภูมิศาสตร์

Margarine Spreadability

Situation

A manufacturer of different types of margarine wanted a quantifiable, consistent way to measure and ultimately better control the texture of their different products. They specifically wanted to know the spreadability of their packaged margarine.

A manufacturer of different types of margarine wanted a quantifiable, consistent way to measure and ultimately better control the texture of their different products. They specifically wanted to know the spreadability of their packaged margarine.

การแพร่กระจายของเนยเทียม

สถานการณ์

ผู้ผลิตเนยเทียมชนิดต่าง ๆ ต้องการวิธีการวัดปริมาณที่สม่ำเสมอและสม่ำเสมอในการวัดและควบคุมพื้นผิวของผลิตภัณฑ์ที่แตกต่างกันในที่สุด พวกเขาต้องการทราบความสามารถในการแพร่กระจายของมาการีนแบบบรรจุ

ผู้ผลิตเนยเทียมชนิดต่าง ๆ ต้องการวิธีการวัดปริมาณที่สม่ำเสมอและสม่ำเสมอในการวัดและควบคุมพื้นผิวของผลิตภัณฑ์ที่แตกต่างกันในที่สุด พวกเขาต้องการทราบความสามารถในการแพร่กระจายของมาการีนแบบบรรจุ

ผู้ผลิตไม่มีวิธีการวัดว่าสูตรของมาการีนแบบบรรจุนั้นสามารถแพร่กระจายได้ง่ายกว่าและไม่มี พวกเขาต้องการได้รับมาตรฐานพื้นฐานเพื่อให้พวกเขาสามารถเปรียบเทียบสูตรที่แตกต่างกับที่

Greek Yogurt Firmness and Stickiness

Situation

A processor of Greek yogurt was looking for a way to measure the difference between their 0% fat and 2% fat products. Current methods involve sensorial inspections which are very subjective.

A processor of Greek yogurt was looking for a way to measure the difference between their 0% fat and 2% fat products. Current methods involve sensorial inspections which are very subjective.

โยเกิร์ตกรีกความแน่นและความเหนียว

สถานการณ์

ผู้ผลิตโยเกิร์ตชาวกรีกกำลังมองหาวิธีการวัดความแตกต่างระหว่างไขมัน 0% กับผลิตภัณฑ์ไขมัน 2% วิธีการในปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยความรู้สึก

ผู้ผลิตโยเกิร์ตชาวกรีกกำลังมองหาวิธีการวัดความแตกต่างระหว่างไขมัน 0% กับผลิตภัณฑ์ไขมัน 2% วิธีการในปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยความรู้สึก

โปรเซสเซอร์นี้ไม่มีวิธีวัดความแตกต่างของพื้นผิวระหว่างผลิตภัณฑ์ของตน สิ่งสำคัญสำหรับพวกเขาคือต้องรู้ว่าพื้นผิวของผลิตภัณฑ์นั้นคล้ายคลึงกันมากเนื่องจากจากจุดยืนของลูกค้าพวกเขาไม่ต้องการให้ลูกค้าได้สัมผัสกับความแตกต่างอย่างมากของเนื้อระหว่างผลิตภัณฑ์ไขมัน 0% กับผลิตภัณฑ์ไขมัน 2%

ผลผลิตขนมขบเคี้ยวผลไม้และความมั่นคง

ความต้องการ

บริษัท ผลิตขนมผลไม้จำเป็นต้องมีวิธีการวัดพื้นผิวของผลิตภัณฑ์เพื่อให้แน่ใจว่าผลิตภัณฑ์สำเร็จรูปที่สอดคล้องกัน เนื่องจากวัตถุดิบที่ใช้อาจแตกต่างกันไปตามกาลเวลาจึงต้องมีการปรับกระบวนการผลิตให้เหมาะสม วิธีการควบคุมคุณภาพในปัจจุบันเป็นแบบอัตนัยอย่างสมบูรณ์และผลลัพธ์แตกต่างกันไปในแต่ละบุคคล ต้องใช้วิธีการวัดผลิตภัณฑ์อย่างเป็นกลางและเที่ยงตรง

Chewing Gum Bend Strength

Situation

Large food processor was looking for a way to control the texture of two similar products with different recipes. Current methods involved simple sensory testing.

Large food processor was looking for a way to control the texture of two similar products with different recipes. Current methods involved simple sensory testing.

กำลังเคี้ยวหมากฝรั่งโค้ง

สถานการณ์

โปรเซสเซอร์อาหารขนาดใหญ่กำลังมองหาวิธีในการควบคุมพื้นผิวของสองผลิตภัณฑ์ที่คล้ายกันด้วยสูตรที่แตกต่างกัน วิธีการปัจจุบันเกี่ยวข้องกับการทดสอบทางประสาทสัมผัสอย่างง่าย

โปรเซสเซอร์อาหารขนาดใหญ่กำลังมองหาวิธีในการควบคุมพื้นผิวของสองผลิตภัณฑ์ที่คล้ายกันด้วยสูตรที่แตกต่างกัน วิธีการปัจจุบันเกี่ยวข้องกับการทดสอบทางประสาทสัมผัสอย่างง่าย

ผลิตภัณฑ์ทั้งสองมีความเหมือนกันเป็นหลักความแตกต่างคือรสชาติ ปัญหาคือแม้ว่ากระบวนการจะเหมือนกัน แต่พื้นผิวสุดท้ายของแต่ละกระบวนการก็แตกต่างกัน ส่วนผสมเครื่องปรุงที่แตกต่างกันก็คิดว่าเป็นสาเหตุ เนื่องจากพวกเขาไม่มีวิธีการวัดความแตกต่างอย่างไม่มีจุดหมายจึงไม่มีวิธียืนยันสิ่งนี้

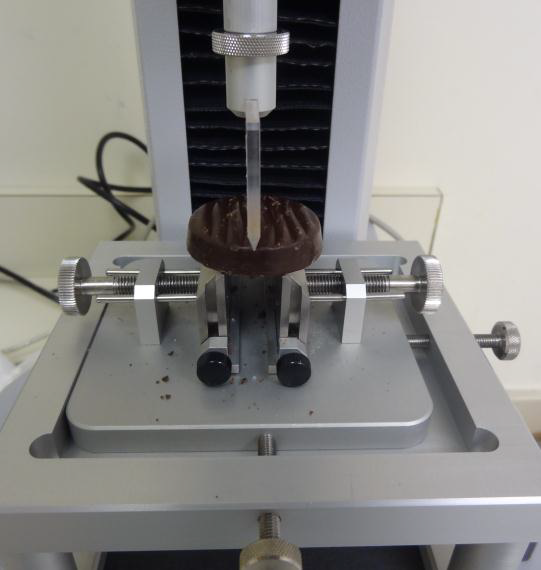

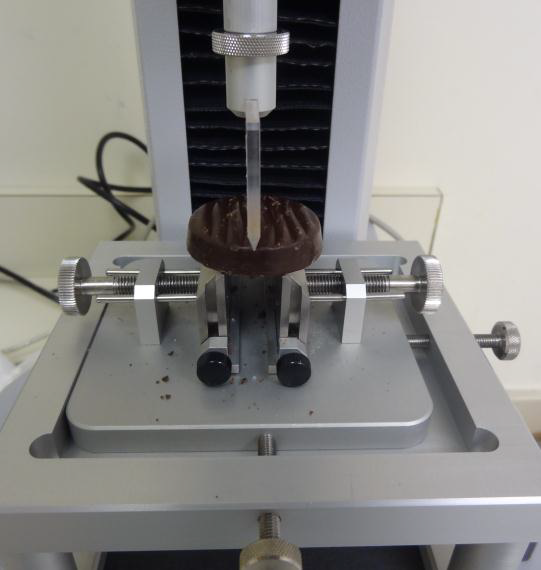

Sweetener Effect on Chocolate Texture

Situation

A confectionery processor wanted to measure the effect on the final texture of their chocolate covered mint product when using a sugar substitute in the formulation.

A confectionery processor wanted to measure the effect on the final texture of their chocolate covered mint product when using a sugar substitute in the formulation.

This processor needed a way to objectively measure the final product texture between the regular and sugar-free formulations and be able to show any differences between them.

ผลของสารให้ความหวานต่อเนื้อช็อคโกแลต

สถานการณ์

หน่วยประมวลผลลูกกวาดต้องการวัดผลกระทบกับพื้นผิวขั้นสุดท้ายของผลิตภัณฑ์มินต์ที่เคลือบด้วยช็อคโกแลตของพวกเขาเมื่อใช้สารทดแทนน้ำตาลในสูตร

หน่วยประมวลผลลูกกวาดต้องการวัดผลกระทบกับพื้นผิวขั้นสุดท้ายของผลิตภัณฑ์มินต์ที่เคลือบด้วยช็อคโกแลตของพวกเขาเมื่อใช้สารทดแทนน้ำตาลในสูตร

โปรเซสเซอร์นี้ต้องการวิธีในการวัดเนื้อสัมผัสของผลิตภัณฑ์ขั้นสุดท้ายระหว่างสูตรปกติและปราศจากน้ำตาลและสามารถแสดงความแตกต่างระหว่างพวกเขาได้

Licorice Firmness

Situation

A processor of candy licorice was looking for a way to measure and compare their two types of licorice product, a regular licorice and a soft licorice. Current methods involve sensorial inspections which are very subjective.

A processor of candy licorice was looking for a way to measure and compare their two types of licorice product, a regular licorice and a soft licorice. Current methods involve sensorial inspections which are very subjective.

ความแน่นของชะเอม

สถานการณ์

หน่วยประมวลผลของขนมหวานชะเอมกำลังมองหาวิธีการวัดและเปรียบเทียบผลิตภัณฑ์ชะเอมทั้งสองชนิดของพวกเขาชะเอมปกติและชะเอมนุ่ม วิธีการในปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยความรู้สึก

หน่วยประมวลผลของขนมหวานชะเอมกำลังมองหาวิธีการวัดและเปรียบเทียบผลิตภัณฑ์ชะเอมทั้งสองชนิดของพวกเขาชะเอมปกติและชะเอมนุ่ม วิธีการในปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยความรู้สึก

โปรเซสเซอร์นี้ไม่มีวิธีวัดความแตกต่างของพื้นผิวระหว่างผลิตภัณฑ์ทั้งสองอย่างเป็นกลาง สิ่งสำคัญคือพวกเขาต้องรู้ว่าพื้นผิวของผลิตภัณฑ์นั้นแตกต่างกันและสำหรับลูกค้าของพวกเขาพวกเขาต้องการให้ตัวเลือกที่แตกต่างกันและแตกต่างกันสองแบบสำหรับลูกค้าของพวกเขา

Cheese - Traditional and Vegan Texture

Situation

As consumers’ diets change, for ethical or health reasons (by choice or recommended), food producers are faced with the challenge of meeting the new requirements, whilst often striving to preserve the established texture.

As consumers’ diets change, for ethical or health reasons (by choice or recommended), food producers are faced with the challenge of meeting the new requirements, whilst often striving to preserve the established texture.

ชีส - เนื้อแบบดั้งเดิมและมังสวิรัติ

สถานการณ์

เมื่อผู้บริโภคเปลี่ยนอาหารเนื่องจากเหตุผลด้านจริยธรรมหรือสุขภาพ (โดยการเลือกหรือแนะนำ) ผู้ผลิตอาหารต้องเผชิญกับความท้าทายในการตอบสนองความต้องการใหม่ ๆ ในขณะที่มักจะพยายามรักษาพื้นผิวที่กำหนดไว้ อาหารมังสวิรัติหลีกเลี่ยงผลิตภัณฑ์นม แต่ชีสมีความนิยมอย่างกว้างขวางโดยผู้บริโภคที่ทันสมัยและดังนั้นผลิตภัณฑ์ที่ผสมผสานรสชาติที่ดีกับปากที่มีความรู้สึกเทียบเท่ากับนมวัวดั้งเดิมทำให้รู้สึกเชิงพาณิชย์ เรากำหนดไว้ว่าเครื่องวิเคราะห์อาห

เมื่อผู้บริโภคเปลี่ยนอาหารเนื่องจากเหตุผลด้านจริยธรรมหรือสุขภาพ (โดยการเลือกหรือแนะนำ) ผู้ผลิตอาหารต้องเผชิญกับความท้าทายในการตอบสนองความต้องการใหม่ ๆ ในขณะที่มักจะพยายามรักษาพื้นผิวที่กำหนดไว้ อาหารมังสวิรัติหลีกเลี่ยงผลิตภัณฑ์นม แต่ชีสมีความนิยมอย่างกว้างขวางโดยผู้บริโภคที่ทันสมัยและดังนั้นผลิตภัณฑ์ที่ผสมผสานรสชาติที่ดีกับปากที่มีความรู้สึกเทียบเท่ากับนมวัวดั้งเดิมทำให้รู้สึกเชิงพาณิชย์ เรากำหนดไว้ว่าเครื่องวิเคราะห์อาห

Tablet Crush Resistance and Break Strength

Situation

What does it take to crush or break a tablet product? Whether it is a vitamin or a dishwasher additive, nobody wants a half-broken tablet left in the bottom of a packet or a whole one that's too hard to crack. A texture analyzer can objectively map the initial fracture point and upper/lower tolerances.

Marshmallow Softness

Situation

Our client produces a marshmallow product, for which the texture (firmness) is a key factor. Their testing method had been a simple sensory method of squeezing the product in the hand, but this did not provide objective data that could be fed back into the manufacturing process.

Our client produces a marshmallow product, for which the texture (firmness) is a key factor. Their testing method had been a simple sensory method of squeezing the product in the hand, but this did not provide objective data that could be fed back into the manufacturing process.

มาร์ชเมลโล่ความนุ่มนวล

สถานการณ์

ลูกค้าของเราผลิตผลิตภัณฑ์มาร์ชเมลโล่ซึ่งพื้นผิว (ความแน่น) เป็นปัจจัยสำคัญ วิธีการทดสอบของพวกเขาเป็นวิธีการทางประสาทสัมผัสที่เรียบง่ายในการบีบผลิตภัณฑ์ในมือ แต่สิ่งนี้ไม่ได้ให้ข้อมูลวัตถุประสงค์ที่สามารถป้อนกลับเข้าไปในกระบวนการผลิต

ลูกค้าของเราผลิตผลิตภัณฑ์มาร์ชเมลโล่ซึ่งพื้นผิว (ความแน่น) เป็นปัจจัยสำคัญ วิธีการทดสอบของพวกเขาเป็นวิธีการทางประสาทสัมผัสที่เรียบง่ายในการบีบผลิตภัณฑ์ในมือ แต่สิ่งนี้ไม่ได้ให้ข้อมูลวัตถุประสงค์ที่สามารถป้อนกลับเข้าไปในกระบวนการผลิต

Hard Candy Break Force

Situation

Too hard! Or just perfect? Bite a hard candy and you know, but can you measure it? This example shows how an expert sensory test (which can be variable between individuals and from day to day) can be quantified and reused in objective mechanized testing. There is more to a perfect candy than just hardness—the way it breaks matters as well. This too can be measured.

กองทัพขนมแหกคุก

สถานการณ์

ยากเกินไป! หรือเพียงแค่สมบูรณ์แบบ? กัดลูกอมแข็งและคุณรู้ แต่คุณสามารถวัดได้หรือไม่ ตัวอย่างนี้แสดงให้เห็นว่าการทดสอบทางประสาทสัมผัสจากผู้เชี่ยวชาญ (ซึ่งสามารถแปรผันระหว่างบุคคลและจากวันต่อวัน) สามารถวัดปริมาณและนำกลับมาใช้ใหม่ในการทดสอบด้วยเครื่องจักรวัตถุประสงค์ มีขนมที่สมบูรณ์แบบมากกว่าแค่ความแข็ง - วิธีการแบ่งเรื่องเช่นกัน สามารถวัดได้เช่นกัน

ความต้านทานต่อการแตกของเม็ดยาและความแข็งแรง

สถานการณ์

ต้องใช้อะไรบ้างในการทำลายหรือทำลายผลิตภัณฑ์แท็บเล็ต ไม่ว่าจะเป็นวิตามินหรือสารเติมแต่งเครื่องล้างจานไม่มีใครต้องการแท็บเล็ตที่แตกครึ่งทิ้งไว้ที่ด้านล่างของแพ็คเก็ต เครื่องวิเคราะห์พื้นผิวสามารถทำแผนที่จุดแตกหักเริ่มแรกและความคลาดเคลื่อนบน / ล่างได้อย่างเป็นกลาง

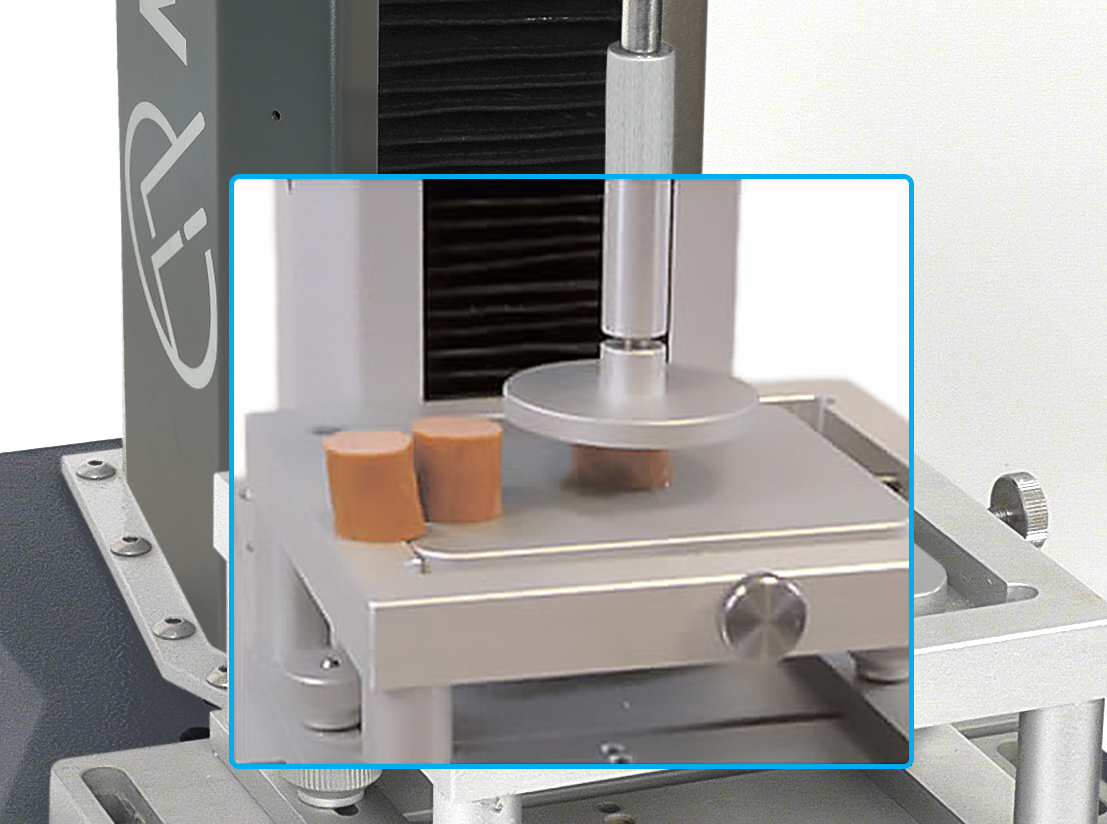

French Bread Staleness

Situation

A producer of ready-to-eat products wanted a way to accurately and objectively determine the degree of 'staleness' of the bread used in their product. This property is critical to the production process.

A producer of ready-to-eat products wanted a way to accurately and objectively determine the degree of 'staleness' of the bread used in their product. This property is critical to the production process.

ความฝืดขนมปังฝรั่งเศส

สถานการณ์

ผู้ผลิตผลิตภัณฑ์พร้อมทานต้องการวิธีในการกำหนดระดับ 'ความไม่สม่ำเสมอ' ของขนมปังที่ใช้ในผลิตภัณฑ์ของตนอย่างถูกต้องและเป็นกลาง คุณสมบัตินี้มีความสำคัญต่อกระบวนการผลิต

ผู้ผลิตผลิตภัณฑ์พร้อมทานต้องการวิธีในการกำหนดระดับ 'ความไม่สม่ำเสมอ' ของขนมปังที่ใช้ในผลิตภัณฑ์ของตนอย่างถูกต้องและเป็นกลาง คุณสมบัตินี้มีความสำคัญต่อกระบวนการผลิต

Pastry Dough Hardness

Situation

Large scale commercial bakery identified a requirement to measure dough hardness as a predictor to process performance in rotary moulder and plug former.

Large scale commercial bakery identified a requirement to measure dough hardness as a predictor to process performance in rotary moulder and plug former.

ขนมแป้งแข็ง

สถานการณ์

เบเกอรี่เพื่อการค้าขนาดใหญ่ระบุความต้องการในการวัดความแข็งของแป้งเป็นตัวทำนายประสิทธิภาพของกระบวนการในการหล่อแบบโรตารี่และปลั๊กแบบเดิม

เบเกอรี่เพื่อการค้าขนาดใหญ่ระบุความต้องการในการวัดความแข็งของแป้งเป็นตัวทำนายประสิทธิภาพของกระบวนการในการหล่อแบบโรตารี่และปลั๊กแบบเดิม

การระบุพื้นผิวและความแน่นของแป้งเป็นคุณลักษณะสำคัญต่อประสิทธิภาพการประมวลผล ถ้าแป้งนิ่มเกินไปมันจะเกาะติดกับแม่พิมพ์และเสียบอุปกรณ์เดิม หากแรงเกินไปก็จะไม่ทำให้ราหรือรอยแตกบน crimping

Tortilla Tear Strength

Situation

The producer of cornflour tortilla products needed a way to determine the texture and the resistance to tearing their products.

Tortilla Tear Strength

สถานการณ์

ผู้ผลิตผลิตภัณฑ์ตอร์ตีญาแป้งข้าวโพดจำเป็นต้องมีวิธีการตรวจสอบพื้นผิวและความต้านทานต่อการฉีกขาดผลิตภัณฑ์ของพวกเขา

ผู้ผลิตผลิตภัณฑ์ตอร์ตีญาแป้งข้าวโพดจำเป็นต้องมีวิธีการตรวจสอบพื้นผิวและความต้านทานต่อการฉีกขาดผลิตภัณฑ์ของพวกเขา

Yeast Firmness

Specification

A processor of yeast blocks was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

A processor of yeast blocks was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

ความแน่นของยีสต์

สเปค

หน่วยประมวลผลของบล็อกยีสต์กำลังมองหาวิธีการวัดเชิงปริมาณที่สอดคล้องกันและในที่สุดการควบคุมพื้นผิวของผลิตภัณฑ์ได้ดีขึ้น วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์ บล็อกยีสต์มีความอ่อนไหวอย่างยิ่งต่อการทำให้แห้งเร็วเกินไปหรือกักเก็บความชื้นและกลายเป็นดินเหนียวหากไม่ได้จัดการและบรรจุในลักษณะ

หน่วยประมวลผลของบล็อกยีสต์กำลังมองหาวิธีการวัดเชิงปริมาณที่สอดคล้องกันและในที่สุดการควบคุมพื้นผิวของผลิตภัณฑ์ได้ดีขึ้น วิธีการปัจจุบันเกี่ยวข้องกับการตรวจสอบด้วยภาพอย่างง่ายและการประเมินความรู้สึกทางประสาทสัมผัสของมนุษย์ บล็อกยีสต์มีความอ่อนไหวอย่างยิ่งต่อการทำให้แห้งเร็วเกินไปหรือกักเก็บความชื้นและกลายเป็นดินเหนียวหากไม่ได้จัดการและบรรจุในลักษณะ

ความแข็งคุกกี้

สเปค

ผู้ผลิตบิสกิตและคุกกี้ชนิดพิเศษต้องการที่จะวัดความแข็งของบิสกิตอย่างเป็นกลาง มีการประเมินตัวอย่างต่าง ๆ สามตัวอย่าง:

•อ่อนเกินไป

• ในอุดมคติ

• ยากเกินไป

Crouton Crunchiness

Specification

A large processor wanted a way to subjectively measure the differences in their “soft” and “crunchy” products. Current method involves just simple subjective sensory that tends to be inconsistent.

Crouton Crunchiness

สเปค

โปรเซสเซอร์ขนาดใหญ่ต้องการวิธีการวัดความแตกต่างของผลิตภัณฑ์ที่ "เบา" และ "กรุบ" วิธีการปัจจุบันเกี่ยวข้องกับความรู้สึกส่วนตัวเพียงอย่างง่าย ๆ ซึ่งมีแนวโน้มที่จะไม่สอดคล้องกัน

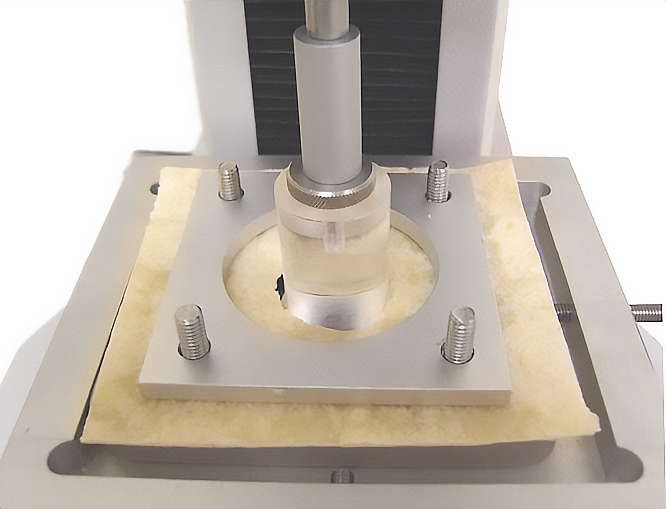

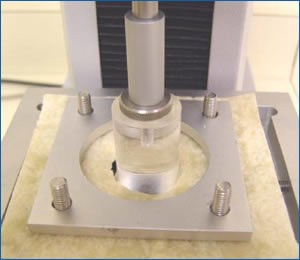

Flatbread Burst Strength

Situation

The following data was gathered for a producer of bakery flatbreads in an effort to develop a new methodology that would allow for consistent and repeatable assessment of their products in an objective manner.

The following data was gathered for a producer of bakery flatbreads in an effort to develop a new methodology that would allow for consistent and repeatable assessment of their products in an objective manner.

แรงระเบิดแบบแฟลตเบรด

สถานการณ์

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับผู้ผลิตเบเกอรี่แฟลตเบดในความพยายามที่จะพัฒนาวิธีการใหม่ที่จะช่วยให้การประเมินผลิตภัณฑ์ของพวกเขาสอดคล้องและทำซ้ำได้อย่างมีวัตถุประสงค์ มีการส่งตัวอย่างทั้งหมดแปดตัวอย่างเพื่อให้ได้ผลลัพธ์พื้นฐานสำหรับผลิตภัณฑ์หลายประเภท มันเป็นสิ่งสำคัญสำหรับลูกค้าว่าระบบจะนำไปใช้กับผลิ

ข้อมูลต่อไปนี้ถูกรวบรวมสำหรับผู้ผลิตเบเกอรี่แฟลตเบดในความพยายามที่จะพัฒนาวิธีการใหม่ที่จะช่วยให้การประเมินผลิตภัณฑ์ของพวกเขาสอดคล้องและทำซ้ำได้อย่างมีวัตถุประสงค์ มีการส่งตัวอย่างทั้งหมดแปดตัวอย่างเพื่อให้ได้ผลลัพธ์พื้นฐานสำหรับผลิตภัณฑ์หลายประเภท มันเป็นสิ่งสำคัญสำหรับลูกค้าว่าระบบจะนำไปใช้กับผลิ

Cookie Hardness

Specification

A speciality biscuit and cookie manufacturer wanted to objectively measure biscuit hardness. Three different samples were evaluated representing:

• too soft

• ideal

• too hard

Cake Firmness

Situation

A processor of pound cakes knew the textures of their products could be different depending on which formulation was used and therefore needed an objective and quantifiable tool to measure the texture to correlate with the sensory testing.

ความแน่นของเค้ก

สถานการณ์

หน่วยประมวลผลของเค้กปอนด์รู้ว่าพื้นผิวของผลิตภัณฑ์ของพวกเขาอาจแตกต่างกันไปขึ้นอยู่กับสูตรที่ใช้และต้องการเครื่องมือที่มีวัตถุประสงค์และเชิงปริมาณในการวัดพื้นผิวที่สัมพันธ์กับการทดสอบทางประสาทสัมผัส

คุณภาพของความแน่นเนื้อและความเป็นสปริงถือว่าเป็นเกณฑ์ในการแยกความแตกต่างระหว่างสูตรทางเลือกอย่างมั่นใจ

Bread Softness - White and Whole-wheat

Situation

Wholewheat bread is frequently regarded by consumers as a healthier choice than white bread made from more refined flour. However, the texture of white bread is often regarded as preferable. Can whole-wheat bread be produced with the same degree of firmness as white bread, and can this be objectively measured?

Bread Softness - ข้าวขาวและโฮลวีต

สถานการณ์

ผู้บริโภคมักนิยมบริโภคขนมปังโฮลวีตเป็นทางเลือกที่ดีต่อสุขภาพมากกว่าขนมปังขาวที่ผลิตจากการกลั่นมากขึ้น

Asparagus (Raw) Fibrousness