Texture Analysis SolutionsRice Firmness and Cook Profile

Highlights

- Objective comparative test to check rice supply for mouthfeel against known prepared quality grades for consumer recommendation

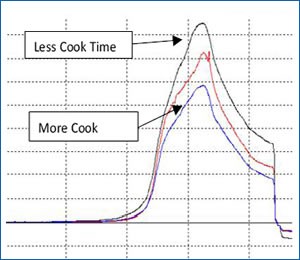

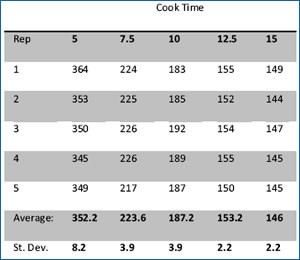

- Repeatable and quick test method to profile texture to cook time using a software-controlled texture analyzer

- Industry-standard fine-blade Kramer fixture to compress and shear through a bulk sample to replicate an initial chew action

- Quantified hardness texture attribute correlated to ideal mouthfeel firmness as a function of cook time

Application

The texture of rice is very important to how the consumer perceives the quality of the product. Unfortunately, the texture is affected by several different factors during the processing. The first thing that the producer has to determine is the quality of the incoming product. From this “starting point” adjustments in the processing can be made to produce a consistent end product.

The texture of rice is very important to how the consumer perceives the quality of the product. Unfortunately, the texture is affected by several different factors during the processing. The first thing that the producer has to determine is the quality of the incoming product. From this “starting point” adjustments in the processing can be made to produce a consistent end product.

Problem

As with most food products, controlling the texture of rice takes constant manipulation of the processing controls to produce a product that is not only consistent but also up to quality standards. Changes in the incoming raw ingredients are especially important with rice.

As with most food products, controlling the texture of rice takes constant manipulation of the processing controls to produce a product that is not only consistent but also up to quality standards. Changes in the incoming raw ingredients are especially important with rice.

Different rice breeds along with variations in harvesting can greatly affect the protein and carbohydrate levels in the product. These two characteristics have a great deal of influence on the final texture of the rice.

Solution

Prior to testing, raw rice was cooked using a standard method, drained, and then allowed to cool for a specific time. Rice was then spooned into the CS-2 Thin Blade Shear Cell until the cell was full but not packed. The CS-2 cell is based on the design of Kramer Shear Cell. The difference is that it has more blades, closer together. This design is especially helpful when testing small particles like rice, as the pieces tend to fall through the regular shear cell.

Prior to testing, raw rice was cooked using a standard method, drained, and then allowed to cool for a specific time. Rice was then spooned into the CS-2 Thin Blade Shear Cell until the cell was full but not packed. The CS-2 cell is based on the design of Kramer Shear Cell. The difference is that it has more blades, closer together. This design is especially helpful when testing small particles like rice, as the pieces tend to fall through the regular shear cell.

All testing was done using the TM-2 Shear Press at a speed of approximately 90 mm/min. The peak force values from this test are an indication of the firmness of the product. This gives the processor valuable information about the product that they can relate back to things like proper cook time, soak time, etc.

Benefit

• Simple and quick test that gives the manufacturer an objective result that can be related to the quality of the incoming raw product

• Overall consistency and quality of the product can be improved

• Results will help to take the guesswork out of adjustments to the process controls

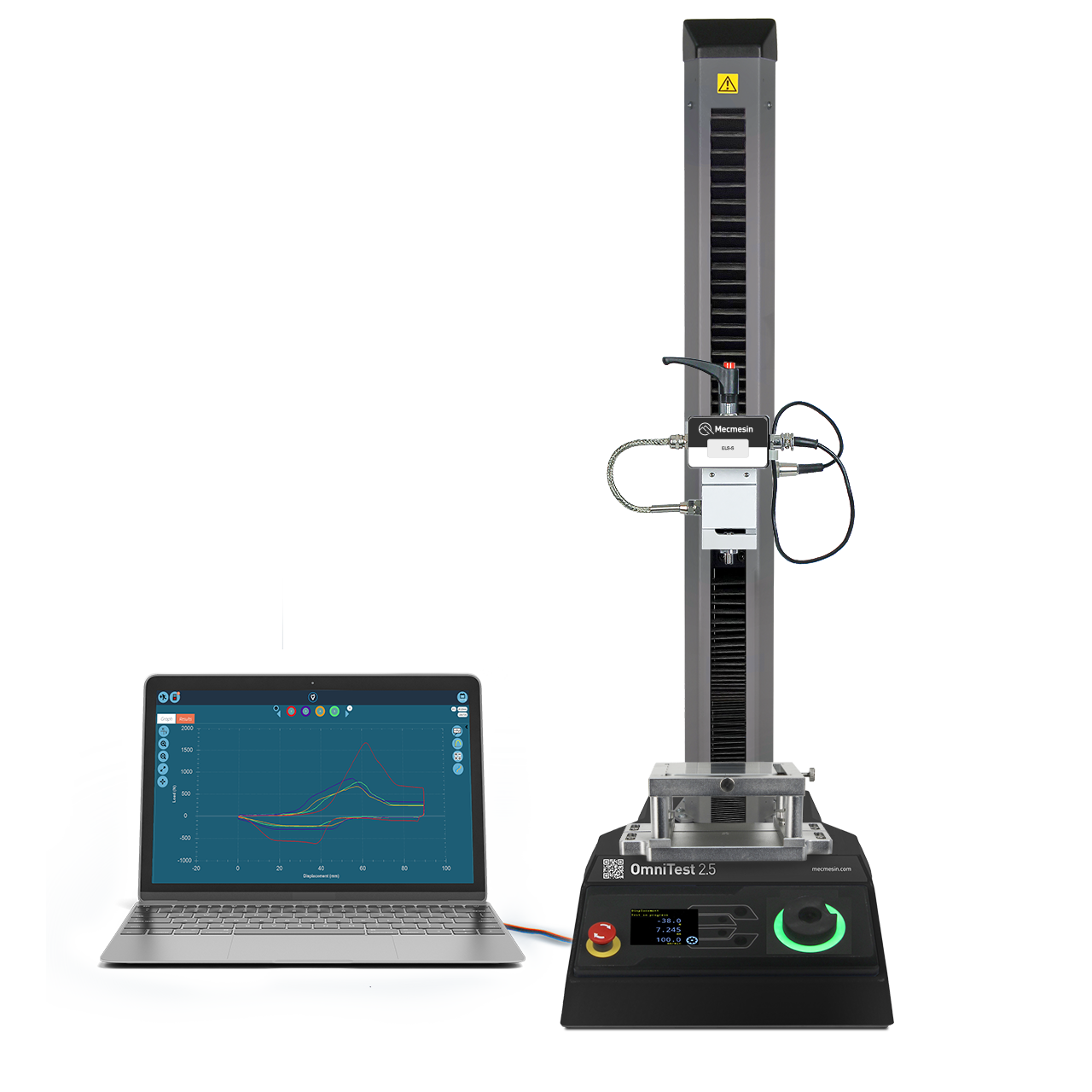

Dedicated Rice Texture Analyzer

The texture of rice is vital to how the consumer perceives the quality of the product.

The Mecmesin Rice Texture Analyzer is a bench-top, software-controlled instrument to measure the sensory mouthfeel of cooked rice and other foods. VectorPro software controls the Texture Analyzer to apply the forces on the test sample, acquires the data and automatically calculates the results which correlate to the correct sensory qualities. The food scientist can examine the graph of force vs displacement and assign peak, average, areas and other values to texture property calculations.

This system gives the rice producer a quantifiable method to benchmark and compare the texture of different rice varieties, optimize the cook profile (to indicate consumer preparation instructions) and check the consistency of supplied raw grains. It can evaluate the impact of variations in harvesting, which affects the protein and carbohydrate levels in rice. These two characteristics have a great deal of influence on the final texture when it is prepared.