Texture Analysis SolutionsCorn Chip Snack Crispness

The Application

A large manufacturer of snack food items was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

A large manufacturer of snack food items was looking for a quantifiable, consistent way to measure and ultimately better control the texture of their product. Current methods involved simple visual inspections and very subjective human sensory evaluation.

Problem

The manufacturer wanted a baseline or “standard” for their fresh product that they could compare other product batches to in a pass/fail scenario. Before our test, they used sensory analysis alone to determine if the product was fresh or stale. However, they wanted a method to quantify the data and visualize the difference in the products. A consistent and repeatable method of measuring and therefore controlling the texture is essential.

Solution

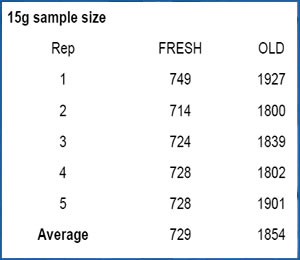

All testing was done using the FTC TM-2 Hydraulic unit with the heavy duty FTA 3000 loadcell and CS-1 Test Cell. The chart to the right exhibits the data collected from running 5 samples of the fresh and 5 samples of the old product at the same speed and with same sample size. The graph demonstrates tremendous difference between fresh and stale products, thus, giving the customer a range of values to use as a baseline moving forward.

All testing was done using the FTC TM-2 Hydraulic unit with the heavy duty FTA 3000 loadcell and CS-1 Test Cell. The chart to the right exhibits the data collected from running 5 samples of the fresh and 5 samples of the old product at the same speed and with same sample size. The graph demonstrates tremendous difference between fresh and stale products, thus, giving the customer a range of values to use as a baseline moving forward.

Benefits

Quick and easy test that gives repeatable, objective results that are nearly real time with the processing Allows for more concise control of textural attributes of the product Reduces the possibility of downtime due to a product that does not meet quality standards