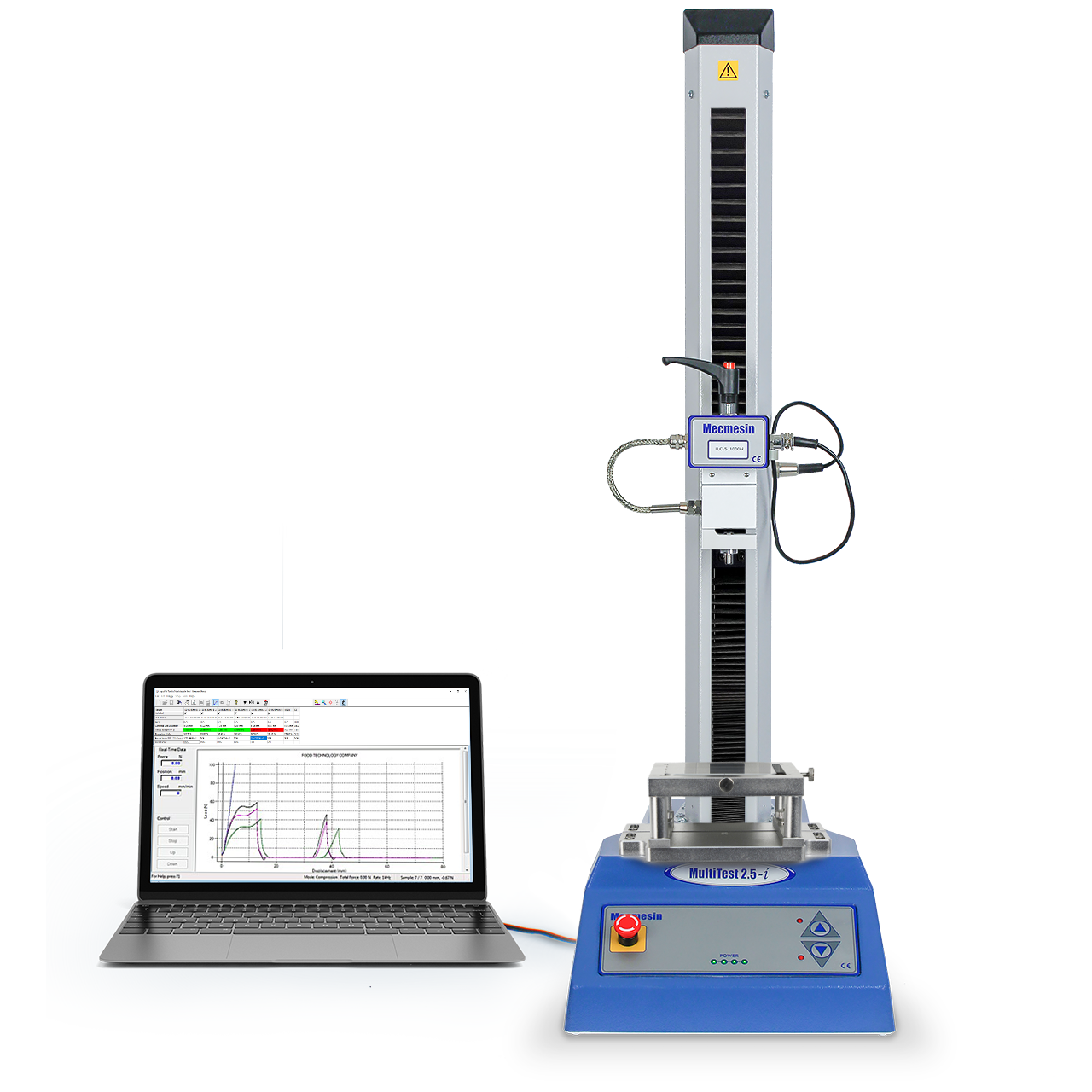

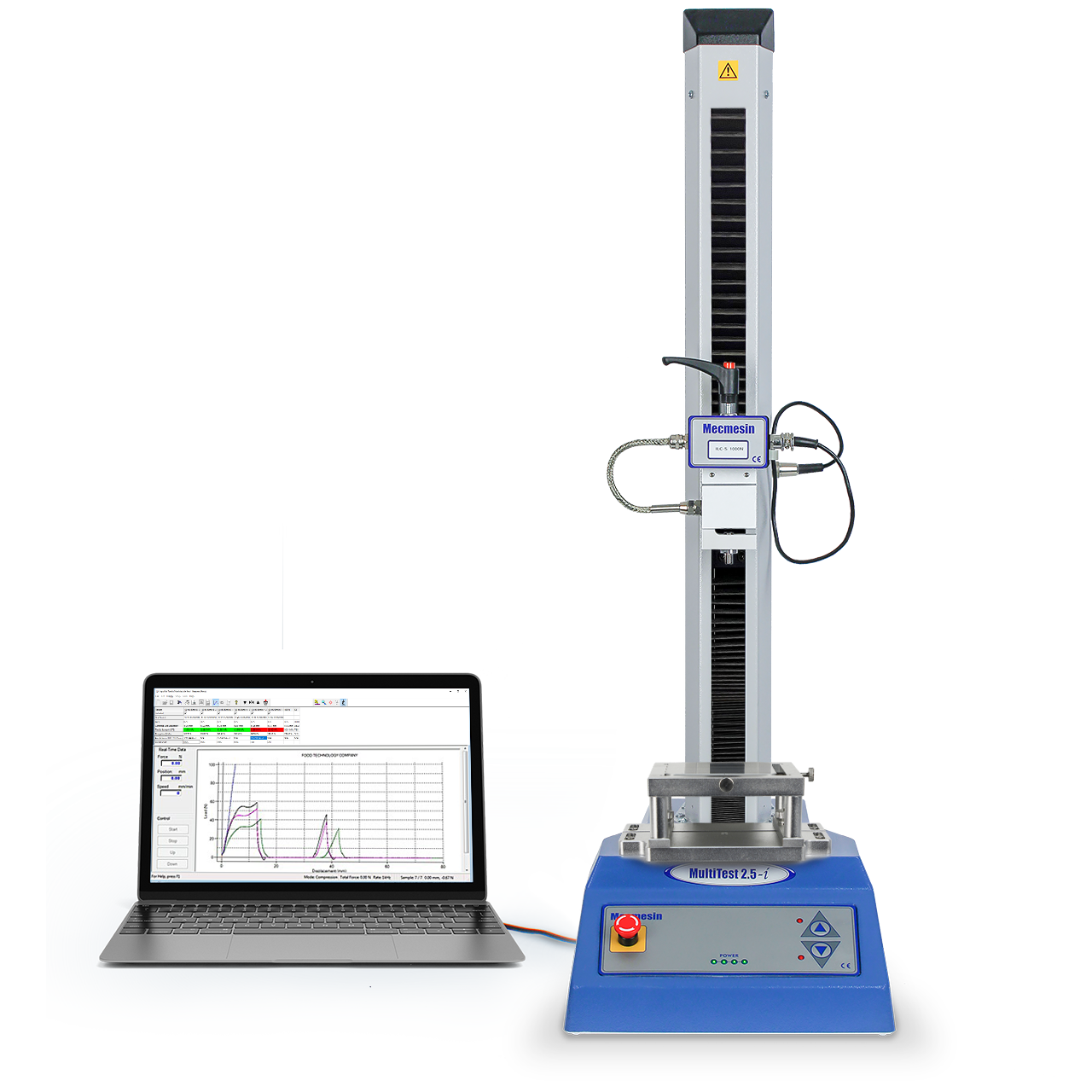

The MultiTest-i Texture Analyzer is a versatile tensile and compression tester controlled by software running on a PC.

The single-column range fits neatly on your bench-top and is ideal for product texture testing applications according to your own test methods.

A wide range of tensile grips, bend jigs and compression fixtures make the single-column MultiTest-i easy to use for measuring tension and compression, from as little as 2 N right up to 5 kN.

The MultiTest-xt is a versatile tensile and compression tester controlled by software running on a touchscreen console.

The single-column range fits neatly on your bench-top and is ideal for product testing applications according to your own test methods.

A wide range of tensile grips, bend jigs and compression fixtures make the single-column MultiTest-xt easy to use for measuring tension and compression from as little as 2 N right up to 5 kN.

Advanced software-controlled tensile and compression tester powered by our trusted testing software, Emperor Force.

- Product and component testing

- Quality control environments

- Research and development labs

- Capacity:

2 N to5 kN

The single-column range is an ideal bench-top device for product testing applications according to your own test methods.

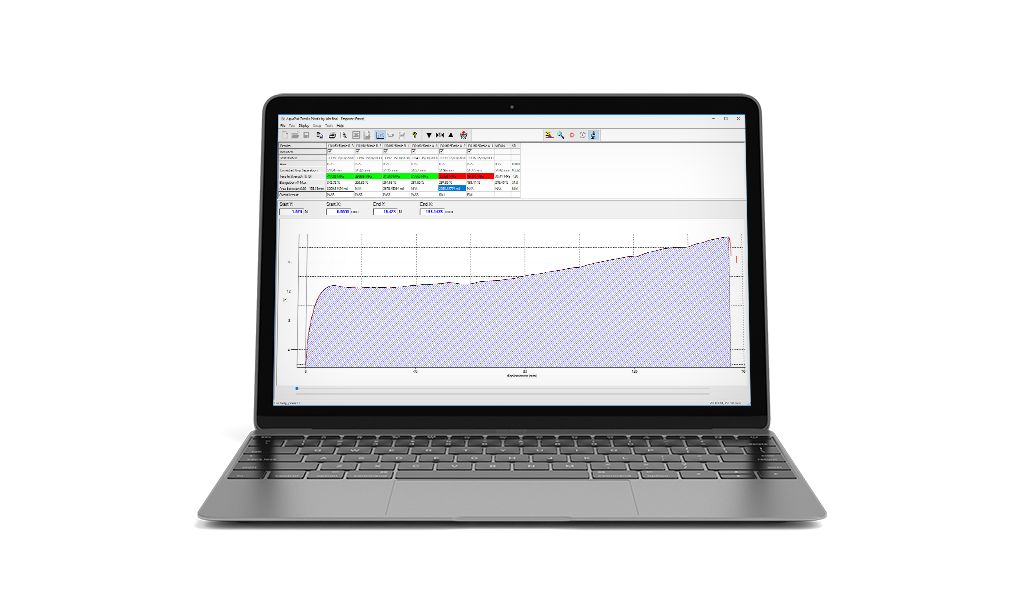

Emperor™ Force software

Easy-to-use software with almost limitless freedom to design and customise tension and compression tests to suit your needs. Developed by Mecmesin in close collaboration with our customers, Emperor™ is now trusted by over 5,000 companies for the detailed testing and evaluation of their products.

Create simple tests for the production line and more complex laboratory tests to prove design standards are met.

Key features

Create

Intuitive user interface

Build test routines step by step

Favourite one-touch tests

Test

Real-time graph plotting

Display measured and calculated values

Clear pass/fail indication

Report

Standard and customisable templates

Print results to Adobe PDF format

Export results to Excel and SPC packages

Trusted by over 5,000 customers worldwide

Learn more about EmperorExample applications

Gel bloom strength test

Gel bloom strength test Bulk analysis test using a Kramer Shear Cell

Bulk analysis test using a Kramer Shear Cell Shear test on asparagus

Shear test on asparagus Snapping test using a 3-Point Bend fixture

Snapping test using a 3-Point Bend fixture

Overview

Delivering consistency and reliability, the MultiTest-i tensile and compression tester controls all key test parameters such as force, displacement and speed.

Emperor Force testing software drives the test system, removing the inherent variability found in manual testing methods.

A single-column MultiTest-i is designed for measuring forces up to

A compact bench-top design that takes up very little space, with intuitive controls makes the MultiTest-i system easy to use, even for novice operators.

Available in a range of sizes and capacities

For example, you can test high-elongation specimens on the long travel

Our most popular

Mecmesin deliver affordable solutions to please every budget

Customers from industries such as automotive, aerospace, cosmetics, electronics, packaging, pharmaceutical, medical, have all come to rely on Mecmesin as their partner of choice for tensile and compression testing solutions.

Technical specification

For more details about the MultiTest-i range, as well as the full technical specifications, visit our corporate website mecmesin.com (MultiTest-i product specs).

Product brochures

Features

The single-column MultiTest-i testing system comprises four key elements:

Test frame

Ballscrew-driven motorised test frame, design for applying tensile and compressive forces from a few mN up to 5 kN. High-quality construction manufactured under ISO 9001 quality standards.

Dovetailed crosshead design for minimising operator setup time with 'plug and play' (interchangeable) loadcells automatically recognised by the software.

Pre-drilled base plate with threaded holes for configuring a wide range of grips and fixtures. Quick change (QC) adaptors make it even easier to swap grips for performing different tests.

Loadcells

Specially adapted 'plug and play' (interchangeable) loadcells, from 2 N up to 5 kN with outstanding measurement accuracy of ±0.1% or ±0.2% of the sensor capacity.

A calibration certificate (traceable to national standards) is provided as standard with every sensor.

Software

Easily create step by step test routines to your exact testing procedure requirements. Commonly used tests can be run with one-click by the operator from a 'favourites' menu or a configured drop-down list.

Emperor Force testing software runs on a Windows computer, controlling the test frame motor and collecting data at 1,000 Hz from the loadcell and displacement encoder.

Plotting measurement data on a realtime graph enables the operator to see exactly how the specimen is performing. Preset calculations can analyse test data to determine if the specimen has met the quality control pass/fail criteria.

Emperor Force enables the operator to issue test reports as PDFs, as well as exporting data to Excel or the network for further analysis in a Statistical Process Control (SPC) package.

Grips & fixtures

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin design tension and compression grips to hold any size/shape component.

We also have team of design engineers that will work with you and develop the best grip for your specimen, commonly using in-house 3D printing to produce lightweight precision fixtures.

Tension & Compression

Test frame rated capacity

| Model | 0.5 kN | 1 kN | 2.5 kN |

|---|---|---|---|

| N | 500 | 1000 | 2500 |

| kgf | 50 | 100 | 250 |

| lbf | 110 | 220 | 550 |

Dimensions

Throat depth

67 mm (2.6") - 0.5, 1 & 2.5kN models

95 mm (3.7") - 5kN model

NOTE: It is recommended to fit protective bellows, to protect against dust and particle ingress and splash into the column. This reduces the throat depth by 18 mm (0.71")

Height

1616 mm (67") - 0.5kN model

1416 mm (59") - 1kN model

941 mm (37") - 2.5kN model

1082 mm (43") - 5kN model

Width

290 mm (11.4") - 0.5, 1 & 2.5kN models

328 mm (12.9") - 5kN model

Depth

414 mm (16.3") - 0.5, 1 & 2.5kN models

526 mm (20.7") - 5kN model

Weight

31 kg (68 lbs ) - 0.5kN model

27.5 kg (61 lbs) - 1kN model

24 kg (53 lbs) - 2.5kN model

38 kg (84 lbs) - 5kN model

Excluding console, approx. 2.5 kg (5.5 lbs)

Speed

Range

1 - 1000 mm/min (0.04 - 40"/min) - 0.5, 1 & 2.5kN models

1 - 500 mm/min (0.04 - 20"/min) - 5kN model

Accuracy

±0.2% of indicated speed or ±20 µ/min, whichever is greater*

* See help.mecmesin.com for additional info.

Resolution

1 mm/min (0.04"/min)

Displacement

Maximum displacement (crosshead travel)

1186 mm (46.7") - 0.5kN model

986 mm (38.8") - 1kN model

507 mm (20") - 2.5kN model

590 mm (23") - 5kN model

Accuracy

±0.13 mm per 300 mm

(±0.005" per 11.8" travel)

Resolution

0.01 mm (0.0004")

Load

Accuracy

±0.1% or ±0.2% of full scale depending on loadcell selected

Resolution

1:6500

Units of measurement

mN, daN, N, kN, gf, kgf, ozf, lbf

Sampling rate

2000 Hz

Data-acquisition rate

1000 Hz, 500 Hz, 100 Hz, 50 Hz, 10 Hz (user selectable)

Common specifications

Voltage

230 V AC 50 Hz or 110 V AC 60 hz

Operating temperature

10 - 35°C (50 - 95°F)

Humidity range

Normal industry and laboratory conditions, non-condensing

Communications

Digital I/O

6 input, 6 output (TTL)

Output of test results to PC/printer/datalogger (MultiTest-xt)

Yes - Includes auto-export to Microsoft Excel. Also data-export via RS232 port (direct or via USB/Network converter in ASCII format)

Network communications (MultiTest-xt)

Ethernet RJ45, USB for external wireless connectivity

Got a question about a solution? Get in touch and speak to one of our Technical Sales Engineers now...