Texture Analysis SolutionsBreakfast Pastry Crispiness

Highlights

- Reproducible test method to optimize the customer preparation instructions for a hot toasted bakery product

- Repeatable and useful comparison test method using a software-controlled texture analyzer

- Precision bend fixture to flex and potentially snap the product as a measurable indicator of correct cooked physical properties

- Quantified cohesiveness and fracturability texture attributes to assess snap, bend and crispness

Specification

The following study was performed to show the textural differences caused by variation in the cooking methods of the breakfast pastry toaster strudel. Currently, the producer uses sensory in determining how different cook times can affect their product. Their goal is to rely less on the subjectivity of sensory and apply a test method that is more objective. Food Technology Corporation (FTC) was tasked to develop a method that would allow them to do this in a consistent and repeatable way.

Method

Each test replication involved the upper fulcrum moving down to a displacement of 40mm at a speed of 250mm/min. This displacement was selected as it was far enough to cause the samples to break. Samples were prepared in the 3 groups.All testing was done using FTC’s TMS-Pro Texture Analyzer, fitted with a 250N Intelligent Load Cell (ILC). The fixture used for this particular application was the TMS Light-Weight Three Point Bend. This fixture works by supporting the sample between two fulcrums and then using another fulcrum to bend the sample. Even though this test is designed to evaluate the crust of the product, the inner filling is going to affect the results somewhat. This has to be taken into consideration.

- Toasted to Directions

- Under Toasted

- Over Toasted

This was done in order to show how a change in the cooking method affects the overall texture of the crust of the product. After toasting, the samples were allowed to equilibrate to ambient temperature so that any variation would not affect the results.

Results

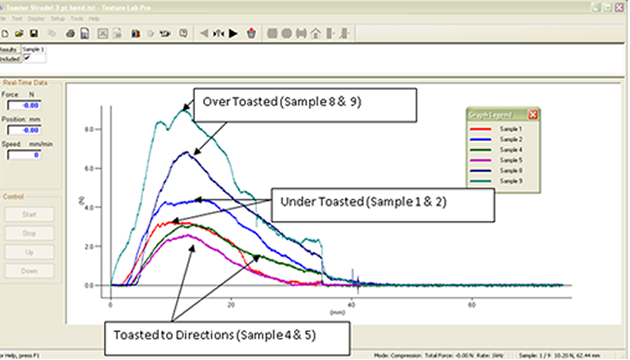

Below is the graphical representation of the samples that were tested. The X-axis is displacement and the Y-axis is force.

The graph above shows the curves that were generated from the 3-point bend test with the Strudel. The graph shows 2 samples that were under toasted, 2 samples that were toasted to directions and 2 samples that were over toasted. When testing food, it is very important to be specific and define what, for example, “under toasted” means, as it can be interpreted differently amongst us. We define the different levels of toasting as such:

- Under Toasted = semi-golden brown on the outside, however the filling is not fully cooked and still partially cold

- Toasted to Directions = golden brown on outside and filling inside is completely cooked and hot

- Over Toasted = burnt and crispy on the outside, filling is hot and completely cooked on inside

Significance

The data shows the Over Toasted sample being the firmest and with the higher peak forces, the Under Toasted samples in the middle and the Toasted to Directions giving the lowest peak forces. The reason the Under Toasted samples are showing firmer than the Toasted to Directions is most likely because of the filling on the inside not being cooked all the way, remaining more solid-like and cold, therefore, harder when the upper fulcrum of the 3-point bend tries to break through it. The Toasted to Directions samples were reading lower forces because the inside filling was cooked all the way and runny, therefore, it doesn’t take much force for the upper fulcrum to break through the strudel. Lastly, the Over Toasted samples register the highest force readings and require the most force to break because the outside was crispy and hard due to over toasting the strudel.

While these results may not be conclusive, further testing would likely produce similar results for the three different cook methods. Once the acceptable ranges of the target product have been established, the producer will have a better understanding of how variations in cooking can affect the final product.